Solar Power Plant Construction Cost

The construction cost of solar power plants depends on several factors such as location, size of the plant, type of solar panel technology used, and installation costs.

For instance, a small photovoltaic autonomous power plant might cost around $1-2 million, while large utility-scale plant could cost several hundreds of millions.

It’s important to note that the initial construction costs are only part of this investment equation; the cost of maintenance, operation, and eventual decommissioning should be considered when evaluating the overall cost of a solar power plant.

What elements make up the cost of a solar power plant?

To determine the costs of a photovoltaic farm, it is first important to identify the factors that affect them.

The initiators of a solar energy project should clearly understand what the investment process looks like and how much work needs to be done in order for this type of project to work properly and bring long-term profit. Naturally, the process of building a solar power plant, like any construction investment, consists of the so-called design part and the execution part.

The cost of building a solar power plant depends on the type of power plant (photovoltaic or CSP), the installed capacity and the quality of the components used.

A typical investment process consists of 3 stages, among which the following can be distinguished:

1. Permitting and preparation of technical documentation.

The engineering stage consists in the selection of the type and installed capacity of the power plant, the choice of construction method and the selection of appropriate equipment. The cost of permitting and engineering services varies from a few hundred thousand euros to several million euros for a large well-executed project with a properly carried out technical analysis, determination of the connection capacity, and many others.

2. Procurement of photovoltaic panels, mounting elements and electrical equipment.

The price of PV panels varies depending on the manufacturer, performance or warranty. To ensure the autonomous operation of a power plant (power supply to an industrial consumer), a significant part of the budget will be spent on batteries, the price of which increases sharply with their capacity and quality. An additional cost will be the purchase of battery charging controllers. In addition, the installation must include robust mounting hardware, overcurrent protection, miles of wiring, remote monitoring sensors, and expensive computer systems.

3. Construction work and installation.

Both general construction works and the direct installation of a solar power plant should be carried out by specially trained teams of professionals with relevant experience. The final cost depends on the characteristics of a particular facility, the complexity of preparing the land and its remoteness from transport hubs and roads. The place where the panels will be installed is also of great importance. Thus, we are talking about costs amounting to hundreds of thousands of euros for each megawatt of installed capacity.

Construction costs in the case of a traditional photovoltaic power plant are divided by some experts into so-called direct and indirect costs, as shown in the table below.

This classification is conditional and can be used to better understand the types of costs expected by investors / owners of the project’s PV during the construction process.

Table: Main cost elements of a 1MW photovoltaic farm.

Direct costs (90-95%) | Indirect costs (5-10%) |

PV modules (40-45%) | Permitting |

Inverters (6-10%) | Engineering project |

Metal load-bearing structures (15-17%) | Financial modeling |

DC and AC cable lines (5-6%) | Geodetic services |

Electrical protective equipment (1-2%) | Construction site supervision |

Electrical substation (15-20%) | Access to engineering communications |

High/medium voltage lines (5-8%) | Construction site security |

Fences, cameras and security measures (3-4%) | Construction insurance, etc. |

Other engineering elements, depending on the requirements of the investor, such as improved lighting and access roads (5%) |

The construction of a photovoltaic farm must be very carefully planned.

Particular attention should be paid to issues that ensure long-term and trouble-free operation, and therefore guarantee a stable profit. Inverters and photovoltaic modules are the most important elements of such projects, which, if properly executed engineering / construction work, have a decisive impact on power generation.

Of course, it is worth betting on trusted manufacturers who have been operating in the market for a long time, which, in case of any problems, will allow for an effective complaints process.

The construction of a solar power plant is also associated with costs that do not depend solely on the decision of the investor, such as rules for connecting to the grid, parameters of existing electrical substations and their equipment.

Depending on the country and the specific location of the project, these factors can vary, and therefore it can be difficult to predict the exact scope and final cost of the work.

This requires careful engineering studies and close interaction with local energy companies / regulators, which also results in additional costs at the planning stage of the investment project.

As we can see, the cost of building a solar power plant can vary significantly within the same capacity. This is influenced by the choice of solar technology and equipment, which differ in productivity, quality, service life and many other parameters. Based on the experience of modern photovoltaic projects, we get a cost of at least 400-500 thousand euros per megawatt. It should be noted that for the so-called CSP-projects, the costs can be many times higher.

Construction cost of concentrated solar power plants (CSP)

Traditional photovoltaic power plants based on PV panels have a huge disadvantage.

This is low generation stability during the day. So-called concentrated solar power plants (CSP) provide greater grid stability compared to photovoltaics. This type of power plant began to develop actively only in the 2010s, so it is still considered a relatively young and expensive technology.

One of the world’s first large commercial CSP power plants capable of generating electricity relatively uniformly around the clock was a 20 MW concentrated solar power plant in Spain, built in 2011. In September of that year, the US Department of Energy issued a loan guarantee of almost $740 million to finance the construction of a new 110 MW solar power plant in Nevada.

Later, similar projects of a larger scale were implemented in many countries. For example, the famous Ouarzazate Solar Power Station (Morocco) consists of several phases, including CSP phases and photovoltaics.

The total installed capacity of this power plant is 580 MW, and the cost of the project is estimated at $2.5 billion.

These power plants use the energy of the sun to heat a heat carrier, whether it be water or molten salts, to produce steam. The latter drives turbines that produce electricity at any time of the day. A typical CSP power plant consists of many thousands of square meters of mirrors that are used to concentrate sunlight into a single point, acting like a huge magnifying glass. The fluid that flows past the beams’ concentration point is then heated and uses the heat to drive turbines.

Obviously, the cost of such power plants is much higher than photovoltaics due to the huge costs of turbine equipment and the coolant delivery system. In 2010, the cost of building a concentrated solar power plant was estimated at 9 million euros per megawatt of installed capacity.

Despite technical advances, the cost of such projects is still at least 10 times higher than photovoltaics.

Payback period calculation for solar power plants

A professional calculation of the payback period for a specific solar energy project is carried out using specially developed financial models.

For most solar photovoltaic power plants, the payback period varies from 4-5 years for advanced bifacial solar panels to 8-10 years for older technologies. These are small numbers, given the actual life of solar farms of 20-25 years with relatively simple and inexpensive operation and maintenance.

The main investment costs in the case of traditional photovoltaic power plants are PV panels and inverters, which together usually account for about 60% of the total cost of building a solar power plant. In practice, these cells are rarely replaced during the first decades of operation, since for modern photovoltaic panels, the degradation of silicon cells does not exceed 0.5% of the rated power per year.

The service life of modern inverters reaches 25 years.

All this in total suggests that the next major investment in the modernization of the solar power plant may be required by the owner in about two decades, which is 3-4 times longer than the estimated payback period of the investment project.

Operating costs for the vast majority of solar projects (primarily for photovoltaics) are low. In the latter case, the owner does not need to replace the coolant, nor any significant costs for materials or spare parts. Staffing is also inexpensive. For example, maintenance of small traditional solar PV power plants with a capacity of 1 to 5 MW or more requires only 2-4 specialists.

For larger projects, the number of personnel per megawatt of installed capacity can be even lower due to economies of scale and the bundling of some functions.

All modern solar power plants are equipped with highly efficient automated control and monitoring systems. These systems allow the technical team to monitor key power plant parameters online and manage most processes remotely, so the need for manual maintenance is minimal.

The estimated life of modern solar power plants can reach 25-30 years, but this is possible only with professional engineering design, high-quality construction and installation, use of advanced technologies, equipment and materials. As with any major construction project, some of the project’s technical deficiencies may only become apparent after the first 2-5 years of operation, so investors should pay the greatest attention to finding experienced contractors.

As for the warranty service of equipment and individual components of the solar PV power plant and the terms of their service, this issue in the case of large projects is usually resolved individually based on negotiations between the customer and the manufacturers (suppliers) of the relevant components. The warranty period for most solar panels is 12-15 years, while for inverters this period is somewhat shorter and is only 5-7 years.

The warranty for installation work in the case of a turnkey solar project is also about 5 years. Once again, experience and technology are two keys to the success of a solar energy project in the long term.

Construction cost of large solar power plants: economies of scale

Capital-intensive solar energy projects are flourishing around the world, attracting leading commercial banks, international financial institutions, large private investors, well-known building contractors and engineering firms.

Currently, China, India and the United States have seized the leadership in generating solar energy in the world, followed by the Middle Eastern countries.

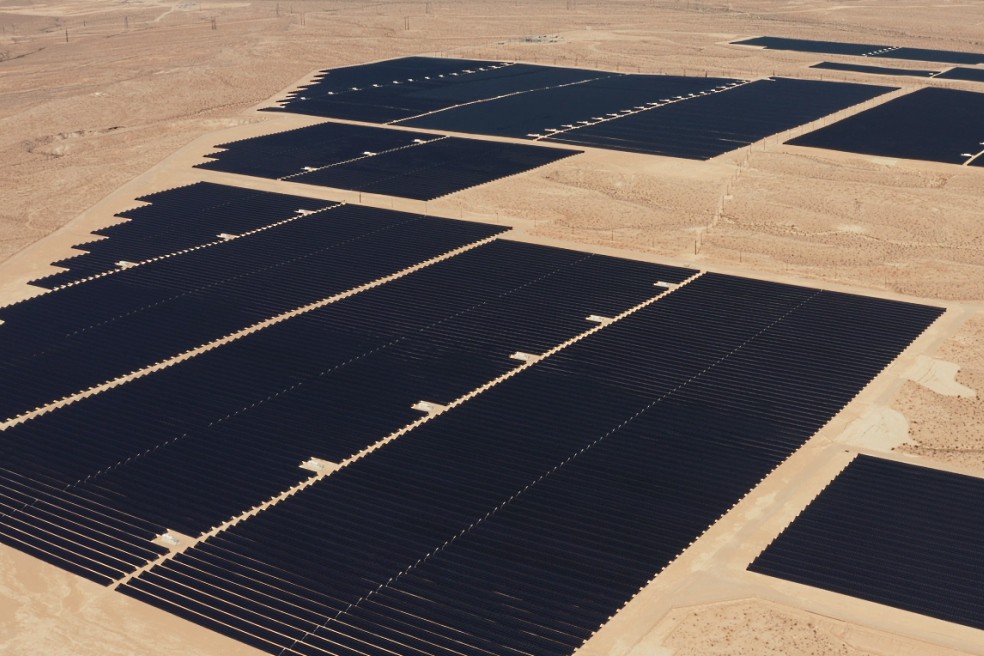

Solar energy is flourishing, especially in the hot regions of Asia, North Africa and Latin America, where huge solar power plants are being expanded and built at a rapid pace.

Historically, the cost of building new solar power plants per megawatt of installed capacity has steadily decreased. This was driven by the rapid development of technology and the scale-up of industrial production of equipment such as PV panels, inverters, etc. Although the rate of price decline in the industry has fallen in recent years and experts say this trend will continue, new projects can still take advantage of competitive advantages, which gives them scientific progress.

As seen in the largest photovoltaic projects in the world commissioned in 2019-2021, the cost of building a large photovoltaic solar power plant ranges from 500 thousand to 1 million euros for each megawatt of installed capacity.

The exception is more expensive concentrating solar power (CSP) projects, as well as some projects planned in difficult conditions and remote locations.

For comparison, examples of ten-year-old projects such as the Topaz Solar Farm in the United States can be cited. This is a 550 MW photovoltaic power plant laid down in 2011 and put into operation in 2014.

Built using the most advanced photovoltaic technology at the time, Topaz cost investors $2.5 billion, which equates to $4.5 million per megawatt of installed capacity.

Table: The cost of the largest solar projects in the world.

Project name | Short description | Installed capacity | Estimated cost |

Benban Solar Park | This power plant is located in Egypt, about 650 km south of Cairo. The project, owned by the State New and Renewable Energy Authority, was completed in November 2019. The photovoltaic panels cover an area of 37 square kilometers, and the annual energy production is planned at 3.8 TWh. | 1,650 MW | $4,0 billion |

Huanghe Hydropower Hainan Solar Park | One of the most expensive solar power plants in the world is located in Qinghai in northwest China and has a capacity of 2.2 GW. It was launched in 2020 and is part of a giant renewable energy complex that is supposed to combine different ways of generating energy, including wind farms and hydroelectric power plants. Ultimately, the complex should reach a capacity of 16 GW. The solar park was built by the Chinese state-owned energy company Huanghe Hydropower Development. | 2,200 MW | $2,2 billion |

Pavagada Solar Park | This project is also known as the Shakti Sthala Solar Power Project. The power plant is located in the state of Karnataka, India. It is the second largest solar farm in India and the third largest in the world. The giant PV panel field, which covers 53 square kilometers, was commissioned in 2019. The facility was designed and built by Karnataka Solar Park Development Corporation Limited and National Thermal Power Corporation. | 2,050 MW | $2,1 billion |

Bhadla Solar Park | The facility is located in Bhadla, in the Indian state of Rajasthan. The region is known for its sunshine and high temperatures, although most of India boasts around 300 days of sunshine a year, making it an ideal place for this kind of investment. The solar power plant was put into operation in March 2020 and has a capacity of 2.25 GW. The entire installation covers an area of 57 square kilometers. | 2,250 MW | $1,3 billion |

In general, the analysis of a number of large solar energy projects shows that economies of scale significantly reduce the cost per unit of installed capacity.

This is the leading driver of the current trend of scaling up solar projects. Energy companies are looking for deserted areas of tens of square kilometers where thousands of PV panels can be compactly placed, saving on land preparation, civil works, installation and maintenance.

Large quantities of equipment are usually purchased at manufacturer discounts, which also save tens of thousands of euros per megawatt installed.

The cost of one megawatt of installed capacity also depends on the host country. Building a solar power plant in developing countries such as India, Morocco, Indonesia, Thailand and Mexico will cost investors significantly less than similar projects in Germany, Australia or the United States. However, advanced technology and economies of scale make it possible to build highly efficient solar power plants even in even in European countries with a temperate climate at prices not much different from India or Egypt.

At the end of 2022, the construction of a large 150 MW photovoltaic plant in Subcarpathian Voivodeship (Poland) was announced.

The expected cost of the project is 85 million euros, which corresponds to about 560 thousand euros per megawatt.

One of the reasons for the decline in the cost of solar power plants is the fierce competition between the leading global manufacturers of photovoltaic cells and other equipment for this sector. Much depends on the situation in the countries that are leaders in the production of polycrystalline silicon.

In particular, recent concerns about pandemic restrictions in China have driven up the price of this strategic material around the world, jeopardizing many photovoltaic projects.

This is not surprising, given that the PRC produces more than 3/4 of the world’s volume of polycrystalline silicon.

Looking for funds to build or upgrade a solar power plant?

ExpoTech with the help of Canadian Funds is not only ready to offer you with the necessary long-term financing, but also a wide range of financial engineering services for large projects. Construction loans, project finance, bank guarantees and much more are available to our clients on flexible terms.

We have already discussed all key trends such as bifacial modules, floating solar and the photovoltaic recycling challenge. However, have you ever wondered what the average cost of a solar farm is in your country? And worldwide? What costs represent the higher percentage in your accounts and, more importantly, how could we decrease these costs.

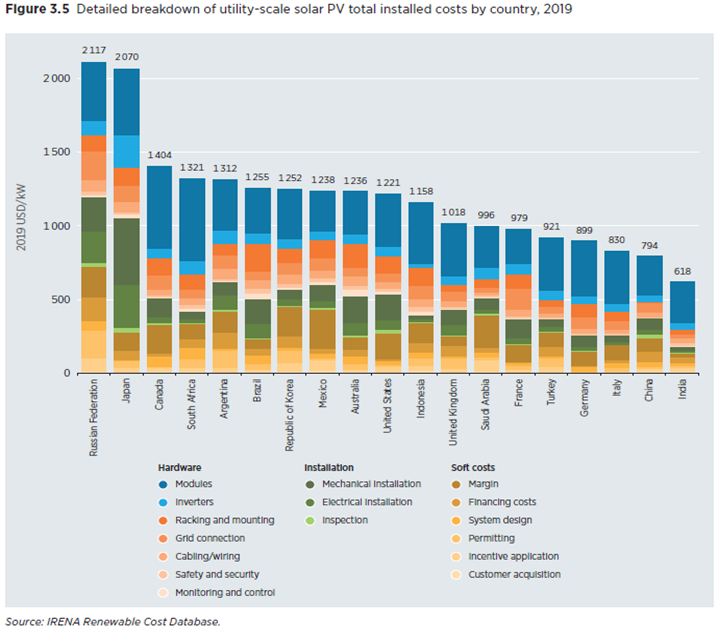

Well, lets begin examining an impressive research paper carried out by IRENAon renewable power generation costs. According to IRENA, the country average for the total installed costs of utility scale solar PV in the studied countries ranged from a low of USD 618/kW in India to a high of USD 2,117/kW in the Russian Federation in 2019. Comparing them, the highest solar farm cost average was about x3.5 more than the lowest, despite the convergence of installed costs in major markets in recent years. The average total installed costs were USD 1191.5/kW.

Take off the hassle of having your PV plant costs on track. Hijack this bill of quantities template for free. +1,000 solar engineers are saving time with it. Download it now

Types of costs on a solar plant

The balance of system (BoS) costs can be broken down into three broad categories: non-module and inverter hardware, installation costs, and soft costs. These three categories can be broken down in more detailed sub-categories.

Non-module hardware costs: Cabling

- All direct current (DC) components, such as DC cables, connectors and DC combiner boxes

- All AC low voltage components, such as cables, connectors and AC combiner boxes

Racking and mounting

- Complete mounting system including ramming profiles, foundations and all material for assembling

- All material necessary for mounting the inverter and all type of combiner boxes

Safety and security

- Fences

- Camera and security system

- All equipment fixed installed as theft and/or fire protection

Grid connection

- All medium voltage cables and connectors

- Switch g ears and control boards

- Transformers and/or transformer stations

- Substationand housing

- Meter(s)

Monitoring and control

- Monitoring system

- Meteorological system ( e.g., irradiation and temperature sensor)

- Supervisory control and data system

Installation costs

Mechanical installation (construction)

- Access and internal roads

- Preparation for cable routing ( e.g., cable trench, cable trunking system)

- Installation of mounting/racking system

- Installation of solar modules and inverters

- Installation of grid connection components

- Uploading and transport of components/equipment

Electrical installation

- DC installation ( module interconnection and DC cabling)

- AC medium voltage installation

- Installation of monitoring and control system

- Electrical tests ( e.g., DC string measurement)

Inspection (construction supervision)

- Construction supervision

- Health and safety inspections

Operations and maintenance (OM costs)

Operations and maintenance, usually found as O&M, costs includes all the expenditure categories since the beginning of PV plant operations. Examples of them are PV module cleaning, monitoring or on-site inspections.

How hard is getting your solar LCOE low and your ROI high. This bill of quantities template is saving a tonne of time to +1,000 solar engineers worldwide. Download it now.

Soft costs

Incentive application

- All costs related to compliance in order to benefit from support policies

Permitting

- All costs for permits necessary for developing, construction and operation

- All costs related to environmental regulations

System design

- Costs for ecological surveys or structural analysis

- Costs for surveyors

- Costs for conceptual and detailed design

- Costs for preparation of documentation

Customer acquisition

- Costs for project rights, if any

- Any type of provision paid to get project and/or off-take agreements in place

Financing costs

- All financing costs necessary for development and construction o f PV system, such as costs for construction finance

Margin

- Margin for EPC company and/or for project developer for redevelopment and construction o f PV system includes profit, wages, finance, customer service, legal, human resources, rent, office supplies, purchased corporate professional services and vehicle fees

We know that costs for electricity generated from new solar PV farms has fallen 82% since 2010. The levelized cost of energy generated by large scale solar plants is around USD 0.068/kWh, compared to USD $0.378 ten years ago. However, what is interesting to see is that these cost reductions were led by hardware components, with modules and inverters accounting for 62% of the global weighted-average total installed cost decline between 2010 and 2019.

Balance of systems costs costs are therefore an important contributor to the declining global weighted-average total installed costs, with 13% of the global reduction coming from lower installation costs, 7% from racking, 3% from other BoS hardware (e.g., cables, junction boxes, etc.) and 15% from a range of smaller categories.

Taking a closer look at the data obtained from IRENA, we can draw the next indicators:

- Although modules on average mean 30% of total installation costs (USD 357.9/kW), in some countries these prices might be quite different. In South Africafor instance, on average these costs may reach up to USD 557/kW which would account to 42.2% of total plant costs.

- On another note, installation costs might also see an important deviation from the average depending on the country. Japan has the highest mechanical installation costs (USD 456.2/kW and 22% of costs) which is more than double the average costs worldwide ((USD 119/kW, 10% of plant’s costs). On the other side of the balance, Indonesia’s mechanical and electrical installation costs only sum up to (USD 41.5/kW and 3.6% of total costs of the plant) in comparison to a x4 times world average of (USD 187.7/kW, 15.8% of costs). This sheds light on Indonesia’s low labor costs.

- Last but not least, it is also interesting to compare the margin costs between countries, which might go from (USD 260.9/kW) in the case of Mexico to as little as (USD 25.6/kW) in Indonesia being the world average (USD 132.9/kW).

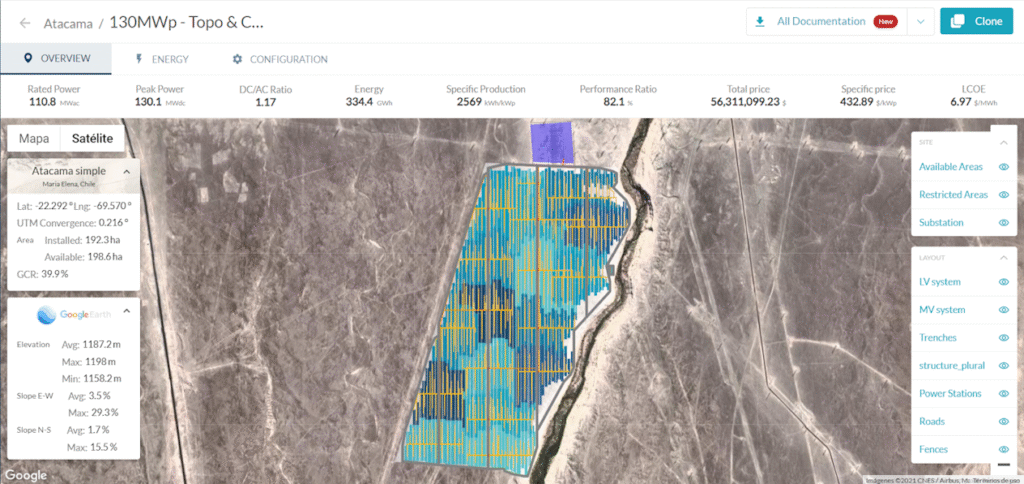

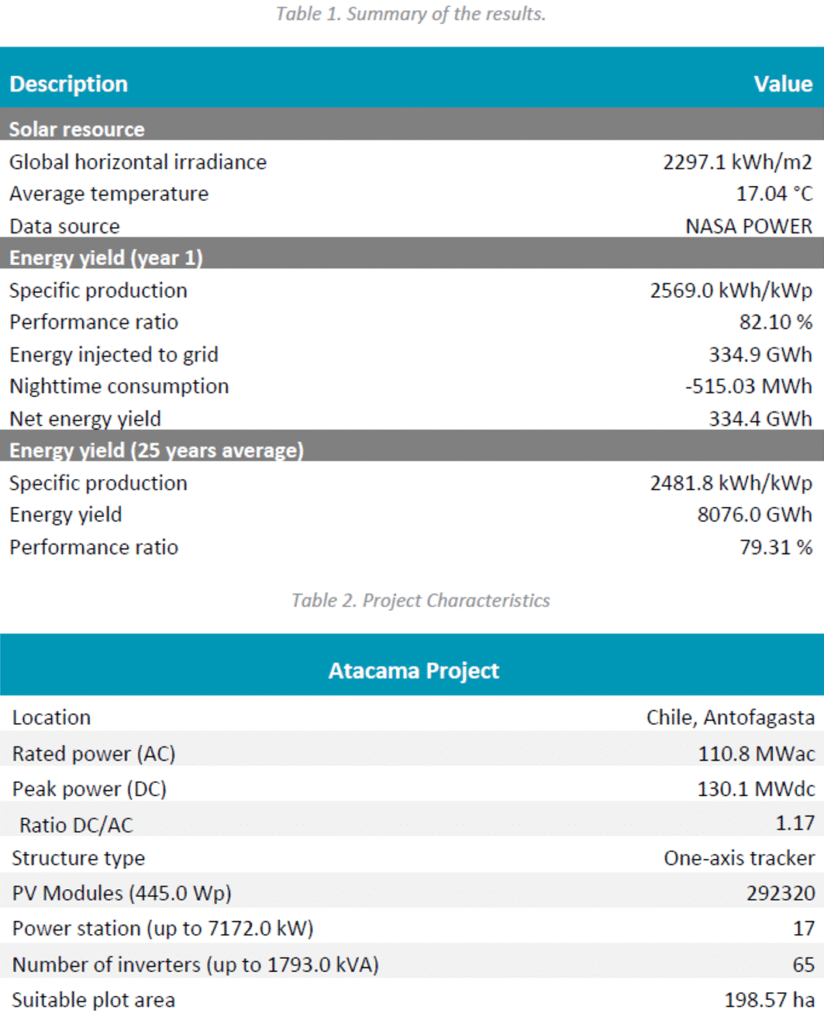

Allocate your costs efficiently: a real case study

Feel free to use our spreadsheet as a template and play around with the different items that form a solar farm: modules, inverters, power stations, trenches, manholes, roads, different types of cables and even miscellaneous things such as surveillance cameras.

Using data, planning and embracing technology are key to decreasing costs

Solar has been the renewable energy with the greatest cost reduction of the last decade. The reasons for this can be summarized mainly in: competitive pressures, greater installer experience, the spread of best practice installation and soft costs, module efficiency improvements and digitalization.

Nevertheless, although these reasons explain the reduction of costs until now, if the curve is to keep its path downward, investing in digitalization and AI technologies is a must.

It is clear that costs may vary vastly depending on your location and the conditions of the plant. However, what we must prioritize is always providing the most accurate preliminary design based on known historical data, to properly plan the project ahead and avoid unexpected costs.

How can we do that?

Technology.

Did you know that recent study by Inderwildi et al. (2020), estimates that digitalisation has the potential to increase carbon abatement by 20%?

Let us introduce RatedPower, a solar modeling tool, that will allow you to perform different simulations to thoroughly analyze the feasibility of different projects, locations and equipment, while optimizing the layout of your solar photovoltaic projects and then obtaining +300 pages of documentation for planning and financial analysis. Watch our introductory video for further information and don’t hesitate to contact us!

Total installed solar power plant costs by country

Category | Cost Component | Russia | Japan | Canada | South Africa | Argentina | Brazil | Korea | Mexico | Australia | United States | Indonesia | United Kingdom | Saudi Arabia | France | Turkey | Germany | Italy | China | India | Average | Total | % total cost | |

1 | Total | Total | 2,117 | 2,070 | 1,404 | 1,321 | 1,312 | 1,255 | 1,252 | 1,238 | 1,236 | 1,221 | 1,158 | 1,018 | 996 | 979 | 921 | 899 | 830 | 795 | 618 | 1,192 | 22,639 | 100% |

2 | Module and inverter hardware | Modules | 399 | 451 | 554 | 557 | 340 | 306 | 340 | 274 | 294 | 358 | 410 | 362 | 282 | 237 | 359 | 375 | 357 | 267 | 278 | 358 | 6,799 | 30% |

3 | Soft costs | Margin | 213 | 124 | 202 | 104 | 144 | 65 | 197 | 261 | 87 | 173 | 140 | 63 | 217 | 117 | 99 | 99 | 104 | 91 | 26 | 133 | 2,526 | 11% |

4 | Installation | Mechanical installation | 231 | 456 | 126 | 46 | 84 | 172 | 67 | 108 | 187 | 180 | 23 | 98 | 76 | 134 | 50 | 77 | 42 | 75 | 31 | 119 | 2,261 | 10% |

5 | BoS hardware | Racking and mounting | 110 | 117 | 118 | 109 | 78 | 182 | 92 | 122 | 161 | 114 | 122 | 47 | 56 | 98 | 47 | 85 | 65 | 9 | 31 | 93 | 1,764 | 8% |

6 | BoS hardware | Grid connection | 193 | 112 | 92 | 53 | 95 |