Hydropower Can Be Categorized Based On Power Output, Head Range, And Operating System Usages. Table 1, Shows The Different Classification Of Hydro-Power Based On The Above-Mentioned Criteria.

|

Classification |

Description |

|---|---|

|

Power Output |

|

|

Large |

Higher than 100 MW |

|

Medium |

10–100 MW |

|

Small |

1–10 MW |

|

Mini |

100 KW–1 MW |

|

Micro |

5–100 KW |

|

Pico |

Less than 5 KW |

|

Head Range |

|

|

Higher head |

100 m and above |

|

Medium Head |

30–100 m |

|

Lower head |

2–30 m |

|

The operating system |

Considering different parameters various types and sizes of a hydropower plant can be built. Operating parameters such considering head as well as flow rate, hydropower plants can be of three types. |

|

Run river type |

In this scheme, power is generated by the natural flow of water, and the flow of water is not controlled. Naturally, it is subject to water shortage during the summer season, and water is filled in a reservoir in the rainy season. Whenever there is a high flow rate exceeding the capacity, then there is water spillage, which means loss of energy. |

|

Reservoir type |

In this scheme, an excess portion of water is stored in the reservoir, and power generation is regulated based on demand. It is dependent on the topology of the land where the plant will be built. |

|

Pumped Storage type |

This scheme utilizes electricity to pump up water from storage located at the bottom portion of a site to the top of the storage. This type of hydro plant works not only as an energy source but also as an energy storage device. But it is quite arduous to find a suitable location for a pumped storage type plant. |

Table 1: Subdivision of Hydro-Power Based on Different Criteria

Among these technologies, Small Scale Hydro Power (SSHP) is the purest form of energy since it emits less pollutant than other Large Scale Hydro Power (LSHP). Besides LSHP has the disadvantage of ecological damage and large transmission loss due to long overhead transmission lines. For these reasons, investors have lost interest while SCHP is gaining worldwide attention. Another significant hydropower technology that has attracted attention is pumped hydro technology. In this technology, water is stored in a high-head variation storage reservoir which is constructed in parallel to a large river. When energy demand is low or there is the availability of a large quantity of water, water is pumped and stored in the reservoir. This reserved water is used when there is a scarcity or when there is a need to generate electricity. In 2018, the total primary energy consumption of Bangladesh was 47 Mtoe and on average 293 kgoe (kilogram oil equivalent) energy is used. At the end of June 2018, only 12.72 TCF of natural gas is in reserve and 3,100 million tonnes of coal is in reserve. The total energy supply by various energy resources in Bangladesh for 2017–2018 is shown in Fig. 1. From Fig. 1 it is depicted that a major portion of energy comes from natural gas.

Fig. 1 Total energy supplied (%) by various resources in Bangladesh.

Among these technologies, Small Scale Hydro Power (SSHP) is the purest form of energy since it emits less pollutant than other Large Scale Hydro Power (LSHP). Besides LSHP has the disadvantage of ecological damage and large transmission loss due to long overhead transmission lines. For these reasons, investors have lost interest while SCHP is gaining worldwide attention. Another significant hydropower technology that has attracted attention is pumped hydro technology. In this technology, water is stored in a high-head variation storage reservoir which is constructed in parallel to a large river. When energy demand is low or there is the availability of a large quantity of water, water is pumped and stored in the reservoir. This reserved water is used when there is a scarcity or when there is a need to generate electricity. In 2018, the total primary energy consumption of Bangladesh was 47 Mtoe and on average 293 kgoe (kilogram oil equivalent) energy is used. At the end of June 2018, only 12.72 TCF of natural gas is in reserve and 3,100 million tonnes of coal is in reserve. The total energy supply by various energy resources in Bangladesh for 2017–2018 is shown in Fig. 1. From Fig. 1 it is depicted that a major portion of energy comes from natural gas.

Hydro Potential in Bangladesh

Hydro energy is one the cleanest source of energy compared to other conventional energy sources that are used for power generation on a massive scale. As both costs of supply and GHG emissions are quite low, this makes hydropower generation an excellent choice for energy harvesting. Bangladesh is bestowed with lots of rivers and rivers play an important role in the livelihood of the people of Bangladesh. Fig. 2 denotes the river network of Bangladesh.

Though Bangladesh is bestowed with lots of rivers, hydropower generation is not up to the mark due to the absence of high head and high flow rate. Resources are limited and proper utilization of these can lead to the generation of sustainable power for fulfilling the ever-increasing demand. Around 20% of the world’s total electricity comes from hydro energy. Bangladesh is also trying to maximize hydropower generation by taking various measures. Kaptai power plant was the first hydropower plant in Bangladesh built with a capacity of 230MW. During rainy seasons, excess rain creates an opportunity to produce more hydropower and that’s why Bangladesh Power Development Board (BPDB) is planning to establish an additional 100 MW capacity plant in this area. Along with large scale hydropower plants, micro-hydropower plants also attracted the attention of people. The first small-scale micro-hydropower plant of Bangladesh was established in Bandarban to meet the energy demand of 140 households and a temple with a capacity of 10 kW Government established a 50 kW micro-hydropower plant in Barkal Upazila, Rangamati.

Fig. 2 Map of the river network of Bangladesh.

Some potential sites for harvesting hydropower have been investigated in Bangladesh. Sustainable Rural energy project surveyed locations for micro-hydro plants in Chittagong district and it was estimated to be 135.5 MW. Sangu and Matamuhuri river basin comprising 87MW and 80 MW of hydro potential capacity is considered suitable for power generation at an affordable cost. The expected annual energy production of the Sangu and Matamuhuri project will be 300 GW/year and 200 GW/year respectively. Brahmaputra river basin has a massive potential of 1,400 MW for large scale power generation.

The north-eastern region of Bangladesh also has a promising potential to contribute to the hydro energy sector in Bangladesh. That’s why, Northeast Regional Water Management Project (FAP-6) under Flood Action Plan (FAP), conducted a preliminary assessment to find out the potential sites and rivers to produce hydro energy. The project mainly aimed at finding the best feasible sites to establish runoff, low head hydropower plants. Potential sites along with flow data are depicted in Table S1 (supplementary data). Considering 5m of head along with mean monthly discharges of these ten sites, they found the overall potential of 161 MW and energy production 1,410 GWh/year. Nine rivers were also found to be suitable from this study. Normally, during the rainy season, there is a high discharge of water and in the winter season, rivers almost dry out. So, power generation will significantly decrease in the winter season. From these nine rivers, it was estimated that annually they will produce 307 GWh and estimated power output will be 35 MW. Potential energy, as well as catchment areas of these rivers, are shown in Table 2.

|

River |

Site |

Catchments area (km2) |

Estimated annual output (MW) |

Estimated annual output (GWh) |

|---|---|---|---|---|

|

Someswari |

Dugapur |

2134 |

5 |

43 |

|

Jadukata |

Saktiakhola |

2513 |

13 |

115 |

|

Jhalukhali |

Dalura |

448 |

5 |

45 |

|

Sarigoyain |

Lalakhal TG |

802 |

3 |

30 |

|

Lubha |

Mugulgul |

724 |

3 |

27 |

|

Dhalai |

Khalasadaq |

342 |

2 |

15 |

|

Umium |

Chalelhnapur |

518 |

2 |

20 |

|

Bhugai |

Hatipagar |

453 |

1 |

6 |

|

Darang |

Ghosegaon |

381 |

1 |

6 |

|

Total |

35 |

307 |

Table 2: Hydro-power Potential in Meghalaya Rivers of the Northeast Region

In 1981, BPDB and Bangladesh Water Development Board (BWDB) conducted a survey across the country to find out the possible hydro sites for small-scale hydropower plants. This study found 19 feasible sites for the generation of hydro-electricity which are shown in Table 3

|

Location |

Cross Sectional area (m2) |

Lowest flood level (m) |

Highest flood level (m) |

Power (kW) |

|---|---|---|---|---|

|

Nunchari Tholi Khal, Khagrachari |

11 |

0.06 (May) |

3 |

5 |

|

Sealock Khal in Bandarban |

25 |

0.15 (April) |

4 |

30 |

|

Taracha Khal in Bandarban |

35 |

0.1 (April) |

6 |

20 |

|

Rowangchari Khal in Bandarban |

30 |

0.1 (April) |

5 |

10 |

|

Hnara Khal in Kamal Chari, Rangamati |

20 |

0.15 (May) |

4.20 |

10 |

|

Hnara Khal in, Hang Khrue Chara M ukh, Rangamati |

25 |

0.12 (May) |

4 |

30 |

|

Monjaipara micro hydropower Unit |

15 |

0.50 |

1 |

10 |

|

Bamer Chara irrigation Project |

10 |

Table 3: Prospective Sites for Micro Hydropower Development in Chittagong Hill Tracts

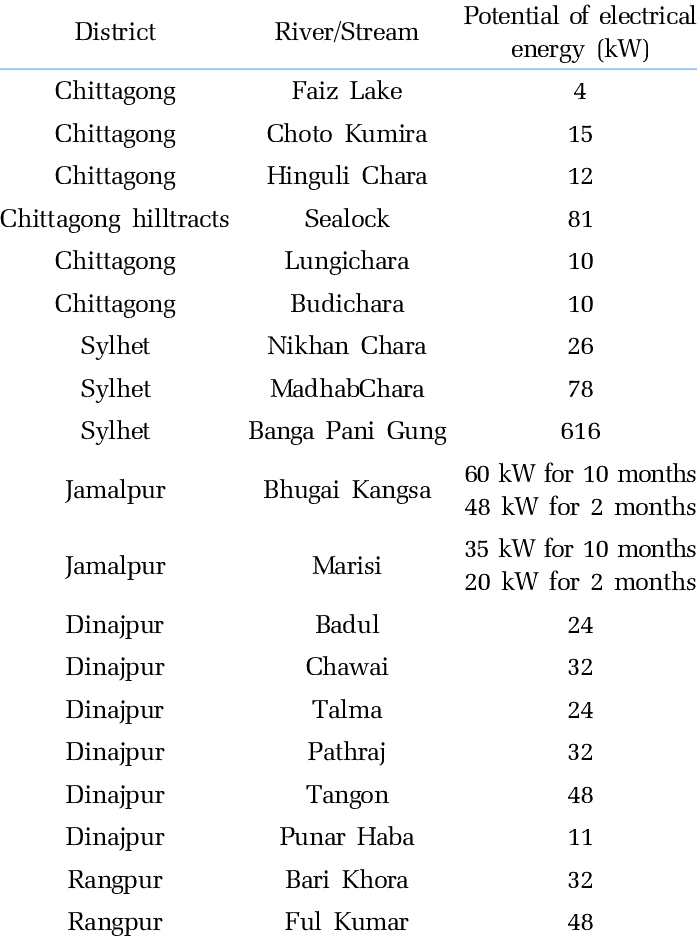

After three years, in 1984, a team of Chinese experts found 12 potential sites in the hill tract areas of Bangladesh to produce hydropower. Among these sites Mahamaya Chara which is located in Mirsharai, Chittagong has the highest potential to develop a small-scale hydropower plant. From feasibility study of Mahamaya Chara it was found that hydroelectricity can be produced throughout the year except in April and May. There is a proposal to construct a dam in Mahamaya Chara which will encompass an area of 10.5 km2 to reserve water and provide irrigation facilities. A mini-hydro plant will be established at the foot of dam and reservoir water will run this plant. The Hill tract of Bangladesh has enormous potential for hydro energy because of numerous small rivers and canals. Local Government Engineering Department (LGED) has been trying to employ hydro energy resources to meet the energy demand in hill tract areas. As a result, LGED located several prospective sites of remote hill tract region of Bangladesh. Prospective sites along with power generation potential are given in Table 4.

|

District |

River/Stream |

Potential of electrical energy (kW) |

|---|---|---|

|

Chittagong |

Faiz Lake |

4 |

|

Chittagong |

Choto Kumira |

15 |

|

Chittagong |

Hinguli Chara |

12 |

|

Chittagong hilltracts |

Sealock |

81 |

|

Chittagong |

Lungichara |

10 |

|

Chittagong |

Budichara |

10 |

|

Sylhet |

Nikhan Chara |

26 |

|

Sylhet |

MadhabChara |

78 |

|

Sylhet |

Banga Pani Gung |

616 |

|

Jamalpur |

Bhugai Kangsa |

60 kW for 10 months |

|

48 kW for 2 months |

||

|

Jamalpur |

Marisi |

35 kW for 10 months |

|

20 kW for 2 months |

||

|

Dinajpur |

Badul |

24 |

|

Dinajpur |

Chawai |

32 |

|

Dinajpur |

Talma |

24 |

|

Dinajpur |

Pathraj |

32 |

|

Dinajpur |

Tangon |

48 |

|

Dinajpur |

Punar Haba |

11 |

|

Rangpur |

Bari Khora |

32 |

|

Rangpur |

Ful Kumar |

48 |

Table 4: Potential Small Hydropower Sites Identified by BPDB and BWDB

Sitakunda, Richang, as well as Toibang of Chittagong, have the potential to establish micro-hydropower plant. Teesta barrage is the largest irrigation project in Bangladesh along with 19 potential sites for power generation. An overall percentage of electricity production from hydropower resources in Bangladesh from 1971 to 2018 is shown in Fig. 3.

Fig. 2 Map of the river network of Bangladesh.

Small Scale Hydropower Technology

Small-scale hydropower technology is a major subclass of renewable and sustainable energy and is getting worldwide attention due to its major advantage from an environmental perspective, the abundance of resources, and increased efficiency. Bangladesh has a huge possibility of SSHT because of its plethora of rivers and canals which provide abundant water for hydropower generation. Despite this, SSHT nearly contributes to 2.34% of electricity generation in Bangladesh. To increase the SSHT generation potential it is required to review SSHT technology for its adoption in Bangladesh.

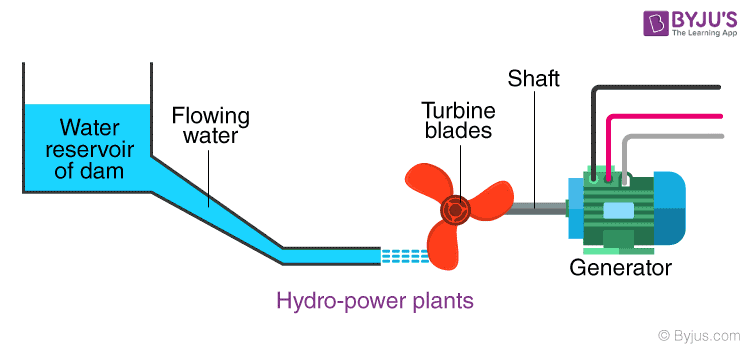

3.1. General Structure and Principle of SSHT

Hydropower plant has several benefits because of its large capacity of energy generation, size of the plant, opulence of resources, and ease of installation and maintenance compared to other energy resources. But its existing efficiency and water power are not easy to extract without a proper generation system. The proper generation of SSHT principally depends on the head and flow. Head refers to water pressure determined by the elevation difference of intake and turbine expressed as vertical distance or force per square area. Flow is defined by the rate with which the water passes, expressed as the volume of water per unit time. These two factors (head and flow) play a major role in the performance of the turbine. Major components of SSHT include water supply and penstock pipe, turbine, electronic controller, distribution system, and electrical load. SSHT’s working principle can be summarized as two-stage:

Firstly, water from reservoir flow hits the pen stack pipe which ultimately hits the turbine runner by which the first energy extraction takes place.

Secondly, the turbine system drives the generator when the shaft has attached with it, which converts the hydraulic power to mechanical power, and the generator to convert the mechanical power to electricity. Finally, this power is distributed through load and grid.

To access the potentiality of SSHT it is necessary to find out the energy generation, hydropower, and mechanical power potentiality. The ratio of these, which is hydropower and mechanical power potentialities, indicates the experimental efficiency of the SSHT. Researchers have shown how to determine the hydro and mechanical power potentiality.

(1) Hp=ρ*g*H* QHp=ρ*g*H*Q

(2) Mp=T*ωMp=T*ω

(3) η=Hp/ Mpη=Hp/Mp

(4) E=w*y*t E=w*y*t

Where,

- Hp= available theoretical power of water in watts

- Mp= mechanical power of the turbine in watts

- η = hydraulic efficiency of the turbine

- E = energy production per year

- ρ = mass density of water in kilo per cubic meter

- g = gravitational acceleration in meter per second square

- H = effective pressure head of water in the meter

- Q = rate of flow in cubic meter per second

- T = torque generated by rotating shaft in Newton-meter

- ω = rotational velocity in radians/second

- w = capacity of the installation

- y = capacity factor (capability of producing electricity in actual field condition expressed as average output to installed capacity over a period of time)

- t = time duration, 8,670 h in one year

Several researchers have conducted experimental and numerical simulations to predict the efficiency of SSHT. The study depicts that modern hydro turbine has 90% efficiency for converting mechanical energy to electricity by reducing the size of the turbine. Computational fluid dynamics is used largely to define the interaction among various components of hydropower, but this process may not able to evaluate loss and flow behaviour.

3.2. Basic Small Hydropower System

3.2.1. Turbine types based on the working principle

The hydro turbine is the principal component of SSHT. According to their work principle, hydro turbines are classified into two types: impulse turbines and reaction turbines. In SSHT suitability of impulse and reaction turbine are based on available water head.

3.2.1.1. Impulse turbine

In an impulse turbine, steam strikes the blades, and moving steam circulates through the blade. Depending upon the water head, impulse turbines have several types which are shown in Table S2 (supplementary data).

3.2.1.2. Reaction turbine

In this turbine, steam hits the blades axially and circulates the blades circumferentially. Depending upon the water head, the reaction turbines have several types Considering medium head (30–100m), there are two types, one is Francis Turbine and another is Pump as a turbine. For ultra-low head which indicates head below 2m, two main types of the turbine are Propeller Turbine and Kaplan Turbine.

3.2.2. Turbine types based on economic and technological point of view

Based on the economic and technological point of view four turbines, namely: Pelton, Francis, Kaplan, and Turgo turbine are widely used because of the low cost of the powerhouse, efficiency generation, and head suitability.

3.2.2.1. Pelton turbine

Pelton turbine consists of a split bucket surrounding particular rims where water jet from penstock is accelerated and made to flow out rapidly causing high-speed water jets to ultimately hit the blade which revolves the wheel generating torque on its shaft and generating power by converting head pressure into kinetic energy. It consists of four parts: nozzle and flow regulator, runner and bucket, casing, and braking jets. Geometric design (diameter of bucket centre, nozzle, jet, and width) and jet velocity of Pelton turbines depends on the speed of the runner, head of water, and rate of flow, and is calculated as using the following equations:

(5) D1=40.8*(H−−√N) D1=40.8*(HN)

(6) B1=1.68*√ (QkH−−√) ))B1=1.68*√(QkH) ))

(7) De=1.178* QkgH−−−√−−−−−−√De=1.178*QkgH

(8) Dj=0.54*√(QH−−√) Dj=0.54*√(QH)

(9) Vjet=0.97*2gH−−−−√ Vjet=0.97*2gH

Where,

- D1= circle diameter describing bucket centre line in meters

- B1= width of bucket in meters

- De= diameter of the nozzle in meters

- Dj= diameter of the jet in meters

- Vjet= jet velocity in meter per seconds

- g = gravitational acceleration in meter per second square

- H = net head of water in meters

- N = speed of the runner

- Q = flow rate in cubic meter

- K = number of nozzles

- D1/B1> 2.7

3.2.2.2. Turgo turbine

Turgo turbine is an impulse type turbine where high-speed water jet hits the turbine blades resulting in reverse flow. Basic parts of this turbine are nozzle, runner and buckets, casing, and breaking jets. Though the Turgo turbine is an extension of the Pelton turbine it has some physical differences. Turgo turbine has numerous advantages over Pelton turbines such as low cost of rotors, high flow rate, and control regulation of flow rate. Additionally, as there are fixed jets in the Turgo turbine it is necessary to maintain a fixed rate of flow.

3.2.2.3. Francis turbine

Francis turbine is designed in such a way that one part of the blade creates pressure difference on others for the production of electricity in hydropower stations. This turbine is the combination of both impulse and reaction types where blades revolve through the reaction and impulse force of the flow. It consists of a spiral casing, stays vanes, guided vanes, runner blades, and draft tube. Although it has several advantages, the inception of this turbine is difficult and cavitation along with dirt creates a serious problem. The geometric shape of this turbine can be found following the equations listed below:

(10) D1=84.5*(0.31+2.49*94*Ns998)*(H−−√N) D1=84.5*(0.31+2.49*94*Ns998)*(HN)

(11) D2= (0.4+94.5Ns)*D1D2=(0.4+94.5Ns)*D1

(12) D3=D10.96+ (3.8*Ns*10−3)D3=D10.96+(3.8*Ns*10-3)

Where,

- D1= exit diameter in meters

- D2= runner inlet diameter in meters

- D3= inlet diameter in meters

- Ns=NPt√H54nNs=NPtHn54

- Pt= turbine power in watt

- NS= specific speed; if NS < 163 then D2 = D3

3.2.2.4. Kaplan turbine

Kaplan turbine is principally based on axial flow reaction where water flows through a runner along the axis of rotation of the runner. The reaction force of water is responsible for turning the Kaplan turbine. Basic components of the Kaplan turbine are scroll casing, guide vane, draft tube, and runner blades. Upstream installed guide vane creates better efficiency of the Kaplan turbine. In Kaplan turbine, the cavitation problem due to pressure drop in the draft tube creates serious problems that can be mitigated by using stainless steel in runner blades. The basic dimension of Kaplan turbines is determined by applying the following equations. Table S3 (supplementary data) shows various types of turbines along with their heads and their suitable operating condition.

(13) D1=84.5*(0.79+1.6*10−3*Ns)*(H−−√N) D1=84.5*(0.79+1.6*10-3*Ns)*(HN)

(14) D2= (0.25+94.5Ns)*D1D2= (0.25+94.5Ns)*D1

Where,

- D1= runner exit diameter in meters

- D2= runner inlet diameter in meters

3.2.3. Penstock & valves

The penstock is used to lead the water to the turbine and materials should be chosen carefully so that it can handle the water pressure going towards the turbine. The diameter of the penstock can be measured via equation (15). Various loss associated with penstock is delineated in Table S4 (supplementary data).

(15) D=C1*C2*Q.43*Ho0.14D=C1*C2*Q.43*Ho0.14

Here,

- D is the diameter of Penstock

- C1& C2 are energy co-efficient & material co-efficient of the penstock,

While designing a hydropower plant there are various losses associated with penstock. This can be determined by Eq. (16).

(16) Hfriction=Hwall+HminorHfriction=Hwall+Hminor

Where,

(17) Hwall=.08*F.F*l*Q2Dn5Hwall=.08*F.F*l*Q2Dn5

(18) Hminor=V22g(Ke+Kb1+Kb2+Kc1+Kc2+⋯+Kv)Hminor=V22g(Ke+Kb1+Kb2+Kc1+Kc2+⋯+Kv)

Here,

- F = Friction Factor

- L = Length of pipe

- Dp= Inner diameter of the pipeline

- Kc1, Kc2are sudden contraction ratio for the different ratio of large to the small pipe diameter.

- V = Velocity of water

- Kb1, Kb2are loss of heads in bends

- Kv= Loss of head through valves

3.3. Previous Work through Numerical and Experimental Simulation

Numerous studies are performed focusing on the flow behaviour of fluids concerning energy transformation, velocity and pressure variation, and water head and its effect on turbines performance.

In the late 1800’s, hydro-power became a feasible method for generating electricity. Decent-sized bodies of water, such as streams or rivers with high elevation drops and high currents are the best candidates for hydro power. The current provides substantial energy, which is utilized when water pushes through the paddles of an installed turbine, creating mechanical energy. If hooked up to an electrical generator, the water-powered turbine will spin the generator, converting mechanical energy to electrical energy. Niagara Falls and the Hoover Dam are two examples of electricity produced in this fashion.

Hydro power is electricity produced from the movement of water.

Hydroelectric power provides about 20% of the world’s electricity.

Hydropower has seen a recent jump in popularity with the World Bank naming it as one viable solution to keep up with growing energy demands while simultaneously avoiding carbon and carbon emissions into the atmosphere.

How a Hydroelectric Power Plant Works

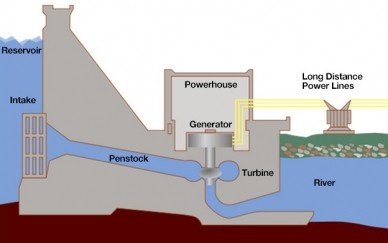

Basically, a modern hydropower plant is comprised of a reservoir, a dam, penstocks, turbines, and generators. The reservoir stores the “fuel” and allow operators to control how much water is fed to the turbines. It also serves as a decanter: Most of the dirt and debris in the water settle at its bottom and away from the intake area.

Water from the reservoir is delivered to the turbines through the intake (dam gates) and penstock. A filtering system at the intake further cleans up the water to ensure that it is relatively free of suspended solids, which could damage the turbine’s blades. Hydraulic systems – the governor, the brakes, the gate controls, and so on – work together to open and close the apertures that allow water to flow downstream from the reservoir.

The water wheel of the past has evolved into the modern turbine. Differing mainly in their blade shape and configuration, the three main types are the Francis turbine, the Kaplan turbine, and the Pelton turbine – named after their inventors. Regardless of design, the turbine converts the kinetic energy of moving or falling water into mechanical energy. The turbine is connected through the shaft to the rotor of a generator that converts the mechanical energy into electricity. For the greatest efficiency, turbines are custom-made for each hydroelectric plant.

Hydro power is electricity produced from the movement of water.

While the concepts of hydropower are simple and straightforward, the operations are anything but. Each modern hydroelectric power plant relies on a multitude of complex systems that monitor, control, and improve conditions to ensure proper operations. Bearings and lubricating systems minimize friction and wear and tear in moving parts. Filters trap the particulate that can abrade turbine blades. Powerful hydraulic systems open and close the penstock gates. Cooling systems keep temperatures under control to prevent overheating and fires in transformers, cables, switchgears, and other electrical and mechanical mechanisms.

Hydroelectricity is produced by utilising the gravitational force of falling water. To this end, the hydropower plant requires a dam. This dam is placed on a source of water, preferably a river. The dam is a massive wall that blocks the flow of the river, therefore, a lot of water collects behind the dam. Near the bottom of the dam, there is an intake from which the water is let into the dam. This intake leads to a drop through the penstock inside the dam. The device used to obtain energy from the falling water here is a turbine. Thermal power plants also use turbines but there are some major differences between the steam turbines and hydro turbines. The turbine is connected by a shaft to the generator. When the water rotates the turbine, electrical energy is generated.

Hydropower plants also have a facility of pumped storage wherein water is kept as a reserve for periods of peak power demand. This is the hydroelectric equivalent of recharging your battery. When the power demand is low, say in the middle of the night, the dam uses a pump to pump the water back up to the reservoir behind it. This water is then used during times of peak power demands.

Hydro power is electricity produced from the movement of water.

Hydroelectricity Verdict

The production capacity of a dam is dependent on the water supply available. Once constructed, a hydropower plant will be operational for decades and provided its water sources don’t run out, it can produce electricity at a constant rate. As mentioned earlier, the output can be easily controlled. The reservoir that forms behind the dam can be used for irrigation or for leisure purposes. Also, once the construction is completed, there is a negligible amount of greenhouse gas emission.

Generation of electricity by hydropower (potential energy in stored water) is one of the cleanest methods of producing electric power. In 2012, hydroelectric power plants contributed about 16% of total electricity generation of the world. Hydroelectricity is the most widely used form of renewable energy. It is a flexible source of electricity and also the cost of electricity generation is relatively low. This article talks about the layout, basic components and working of a hydroelectric power station.

Layout and working Process

The above image shows the typical layout of a hydroelectric power plant and its basic components.

Dam and Reservoir: The dam is constructed on a large river in hilly areas to ensure sufficient water storage at height. The dam forms a large reservoir behind it. The height of water level (called as water head) in the reservoir determines how much of potential energy is stored in it.

Control Gate: Water from the reservoir is allowed to flow through the penstock to the turbine. The amount of water which is to be released in the penstock can be controlled by a control gate. When the control gate is fully opened, maximum amount of water is released through the penstock.

Penstock: A penstock is a huge steel pipe which carries water from the reservoir to the turbine. Potential energy of the water is converted into kinetic energy as it flows down through the penstock due to gravity.

Water Turbine: Water from the penstock is taken into the water turbine. The turbine is mechanically coupled to an electric generator. Kinetic energy of the water drives the turbine and consequently the generator gets driven. There are two main types of water turbine; (i) Impulse turbine and (ii) Reaction turbine. Impulse turbines are used for large heads and reaction turbines are used for low and medium heads.

Generator: A generator is mounted in the power house and it is mechanically coupled to the turbine shaft. When the turbine blades are rotated, it drives the generator and electricity is generated which is then stepped up with the help of a transformer for the transmission purpose.

Surge Tank:

Surge tanks are usually provided in high or medium head power plants when considerably long penstock is required. A surge tank is a small reservoir or tank which is open at the top. It is fitted between the reservoir and the power house. The water level in the surge tank rises or falls to reduce the pressure swings in the penstock. When there is sudden reduction in load on the turbine, the governor closes the gates of the turbine to reduce the water flow. This causes pressure to increase abnormally in the penstock. This is prevented by using a surge tank, in which the water level rises to reduce the pressure. On the other hand, the surge tank provides excess water needed when the gates are suddenly opened to meet the increased load demand.

Types of Hydro-power plants

Conventional plants:

Conventional plants use potential energy from dammed water. The energy extracted depends on the volume and head of the water. The difference between height of water level in the reservoir and the water outflow level is called as water head.

Pumped storage plant:

In pumped storage plant, a second reservoir is constructed near the water outflow from the turbine. When the demand of electricity is low, the water from lower reservoir is pumped into the upper (main) reservoir. This is to ensure sufficient amount of water available in the main reservoir to fulfil the peak loads.

Run-of-river plant:

In this type of facility, no dam is constructed and, hence, reservoir is absent. A portion of river is diverted through a penstock or canal to the turbine. Thus, only the water flowing from the river is available for the generation. And due to absence of reservoir, any oversupply of water is passed unused.

Advantages of a hydroelectric power plant

- No fuel is required as potential energy is stored water is used for electricity generation

- Neat and clean source of energy

- Very small running charges - as water is available free of cost

- Comparatively less maintenance is required and has longer life

- Serves other purposes too, such as irrigation

Disadvantages

- Very high capital cost due to construction of dam

- High cost of transmission – as hydro plants are located in hilly areas which are quite away from the consumers

Potential Small Hydropower

Potential Small Hydropower Sites Identified by BPDB and BWDB

Led by the ongoing global energy crisis, nations across the globe are redoubling their efforts to reduce their dependence on exhaustible and costly fossil fuels and ensure a faster transition to green energy. The geographically diverse South Asian region is rich in a variety of renewable energy sources including small hydro. Small hydro projects offer many benefits when compared to large hydro projects in terms of lower capex costs, smaller gestation periods and less environment concerns. However, small hydro projects suffer from financing issues and waning interest from developers especially due to the more attractive solar power. Thus, small hydro installations have gained traction in very few countries in South Asia. The following article provides a wrap up on the key developments across the different South Asian countries in the small hydro space.

The potential for hydro power is largely untapped in Afghanistan. As per IRENA, the total installed capacity of hydro power projects in Afghanistan was 340 MW in 2021.The government has implemented several initiatives to promote the development of small hydroelectric plants. It has also developed a policy and regulatory framework to encourage private sector investment in the sector. However, the sector faces several challenges, including limited access to finance, inadequate infrastructure, and security concerns. Despite these challenges, the government of Afghanistan is committed to developing the country’s small hydro power potential. It is currently working with development partners and private sector companies to develop a number of hydropower projects.

Bangladesh is a water-rich country, with its rivers and streams providing a significant potential for small hydro power development. Despite Bangladesh’s abundance of rivers, hydropower production is not at par due to the absence of high head and high flow rate. As per IRENA, the total installed capacity of hydro power projects in Bangladesh was 230 MW in 2021. In recent years, the government of Bangladesh has taken a number of measures to encourage the development of small hydro sector. These include the setting up of the Bangladesh Small Hydropower Development Board in 2015 to promote and coordinate the development of small hydro projects. Bangladesh’s first small-scale micro-hydropower plant with a capacity of 10 kW was constructed to meet the energy needs of 140 households and a temple in Bandarban. The government also established a 50 kW micro-hydropower plant in Barkal Upazila, Rangamati.

Bhutan is a small landlocked country in the Himalayas, and its energy needs are largely met by hydropower. In recent years, the government of Bhutan has been investing in small hydro projects to meet the country’s electricity needs. The country has an estimated potential capacity of 30,000 MW of hydroelectric energy, of which 23,760 MW has been identified as economically feasible. The majority of the hydroelectric power capacity is in the form of small hydropower plants with a capacity ranging from 1 MW to 30 MW.

Bhutan has implemented a number of initiatives to promote the development of small hydropower plants in the country. These include providing financial and technical assistance to private investors and communities interested in developing small hydro projects. Case in point, in February 2022, the Druk Green Power Corporation announced the construction of three small hydropower projects, one each at Lhuentse, Zhemgang and Haa, with a total generation capacity of 104 MW. The implementation of the projects would occur in a phased manner.

Small hydro power is a renewable energy resource that has been used in India for many years. It is a cost effective and reliable way of generating electricity in rural and remote areas. The Ministry of New and Renewable Energy (MNRE) has been promoting the development of small hydro power projects since the early 1980s. As of December 2022, the total installed capacity of small hydro power projects in India is 4,925 MW. As per MNRE, the estimated potential of small hydro power is 20 GW across the country. In India, the state of Karnataka presently holds the top spot for utilising small hydro projects, with a total installed capacity of 1280.73 MW.

The Indian government has been encouraging the development of small hydro power plants in the country as part of its renewable energy policy. In November 2022, the Central Electricity Regulatory Commission notified generic tariffs in the range of Rs 4.76-5.84 per kWh for various small hydro projects across states for the financial year 2022-23. In January 2023, a 22.5 MW Ganol Hydro Power Project was inaugurated near Tura in West Garo Hills. In December 2022, the West Bengal State Electricity Distribution Company Limited floated an EPC tender for a 10 MW small hydro project in Lodhama, Darjeeling.

According to the International Finance Corporation, Nepal is the world’s second richest country in terms of inland water resources. Such abundance of rivers, rivulets and tributaries can help the country in harnessing the hydroelectric power not only for domestic use but also for trade. The National Bureau of Asian Research estimated the hydropower potential in Nepal to be 83,000 MW. According to the Renewable Energy Subsidy Policy for 2016, an off-grid pico hydro is eligible for subsidies. Off-grid power projects can be categorised into three sections based on geographical remoteness. A pico hydro project with a capacity less than 5 kW is eligible for a subsidy of up to Rs. 185,000 per kW based on the degree of remoteness, whereas projects with a capacity of 5 kW to 10 kW are eligible for a subsidy of up to Rs 210,000 per kW. In 2021, a small hydro power plant was inaugurated at the Chandannath Municipality in Nepal’s Jumla district. The plant was built with Indian financial assistance of Nepali Rs 26.39 million. The grant from the Indian government was used for the construction of a reservoir tank and the rehabilitation of a small hydropower plant. The power plant would aid about 20,000 residents of Chandannath Municipality in Jumla District.

According to the Pakistan’s Water and Power Development Authority (WAPDA), the country has a hydropower potential of 60,000 MW. The small hydro potential of Pakistan is estimated to be more than 10,000 MW. However, more than 90 per cent potential is still untapped. In 2020, five small hydro power projects were commissioned in the country. The projects include the 500 kw Baila Manoor, 400 kw Biyari Manoor, 300 kw Kotkay Manoor, 300 kw Rajwal, and 150 kw Dum Duma mini hydro power project. The projects will provide an uninterrupted supply of low-cost electricity to approximately 2,000 households, 12 mosques, 10 schools, 120 shops, and a number of tourist facilities in the areas. In the northern regions of the province, the provincial government also started a project to build 328 mini hydro power stations with a total production capacity of 34 MW through non-governmental organisations. The majority of those projects are now commissioned, and the remaining ones are in the final stages. It was reported that out of 328 mini power stations, 17 were to be set up in Mansehra district, with 12 power stations completed and the rest to be completed in the near future.

The Ceylon Electricity Board (CEB), the Srilankan state-owned utility runs the majority of the country’s hydropower stations. CEB is planning to schedule new investments in its Long Term Generation Expansion Plan between 2018 and 2037. The country plans to add 842 MW of major hydro and 215 MW of mini hydro during this expansion plan. In 2020, the energy generated using hydro and marine sources out of the total energy mix of the country was 31 per cent. As reported by the CEB, there are a total of 181 mini hydro projects successfully commissioned in the country that has a total capacity of 353.74 MW.