What is Biogas?

Biogas is a methane-rich gas created through the anaerobic digestion of organic matter. It is typically composed of around 50-70% methane (CH4), along with carbon dioxide (CO2) and includes trace amounts of other gases, such as hydrogen sulphide (H2S), and ammonia (NH3). Biogas serves as a valuable source of clean, renewable energy that can be used for many different purposes, including cooking, electricity, heat production, and even as a vehicular fuel.

Its production not only provides an eco-friendly alternative to fossil fuels but also aids in the effective management of organic waste materials, contributing to waste-to-energy and environmental sustainability objectives. The use of biogas promotes energy independence, rural development, and job creation while enhancing soil fertility through organic fertilizer production. Its decentralized nature ensures reliable energy supply, contributing to energy security and environmental sustainability.

In an era of climate change and the increasing focus of the use of renewable energy sources, biogas has emerged as a crucial clean energy solution. That is why it has become critical to harness its benefits for a greener, more sustainable future.

Advantages of Biogas

A sustainable and environmentally friendly energy source, biogas offers a range of benefits including:

- Reduces greenhouse gas emissions Anaerobic digestion, the process used to produce biogas, helps reduce greenhouse gases like methane which is 21 times worse than CO2.

- Sparks energy independence Biogas is a sustainable source of energy that reduces dependence on depleting fossil fuels. In regions with limited access to traditional energy sources, biogas offers a cost-effective solution that helps alleviate energy poverty.

- Helps manage waste Biogas production provides a scientific way to manage organic waste materials and reduce the environmental impact of landfills. Moreover, anaerobic digestion reduces the odour and pathogen content of organic waste, making it more environmentally friendly and improving local air quality.

- Produces nutrient-rich fertilizer The digestate (residue from biogas production) is rich in nutrients. It can be used as an organic fertilizer to improve soil quality and reduce dependence on synthetic and commercial fertilizers.

- Supports rural development Biogas production benefits rural communities by providing a decentralized source of clean energy and supporting agricultural practices. It also creates jobs in construction, operation, and maintenance of biogas plants.

- Provides wastewater treatment Biogas can be produced during the treatment of sewage and industrial wastewater, providing both energy and a means of treating contaminated water.

- Creates carbon credits Biogas projects can help industries and businesses potentially earn carbon credits under international emissions reduction programme.

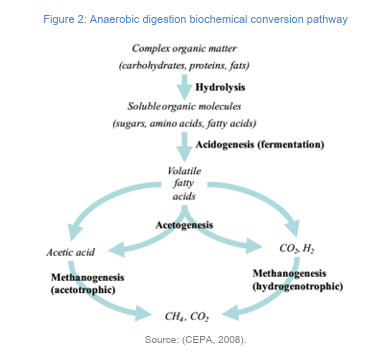

- 1. What is anaerobic digestion? Anaerobic digestion is the natural process in which microorganisms break down organic matter in the absence of air (an anaerobic environment). Anaerobic digestion creates usable products such as biogas and digested material.

- 2. What is an anaerobic digester? Anaerobic digesters are built systems (lagoons or tanks) where anaerobic digestion takes place. Anaerobic digesters manage organic wastes, produce gas and digested materials, minimize odors, reduce pathogens, and reduce solid wastes. Anaerobic digesters are also called “anaerobic digestion systems”, “bio-digesters” or simply “digesters”.

- 3. What is co-digestion? Co-digestion happens when more than one type of organic material is digested at the same time. Digesters are often built for a single purpose. For example, a farmer may build an anaerobic digester to handle cow manure. If the farmer also takes food waste from a local grocery store and puts the food waste in the digester along with the cow manure, it is called co-digestion.

- 4. What is biogas? Biogas is the gas produced when bacteria break down organic matter in the absence of oxygen. It is made up of mainly methane (CH4) and carbon dioxide (CO2), with small amounts of water vapor, particulates, and other gasses, such as hydrogen sulfide (H2S). Biogas can be processed and used for a variety of energy needs, such as the generation of heat, power and fuel.

- 5. How is biogas generated? Inside an anaerobic digester, naturally occurring microorganisms grow in the tank’s oxygen-free environment and break down (digest) the organic matter. As the organic matter decomposes, biogas is created. Once established in a digester, microorganisms will continue to break down organic materials and release biogas in the right conditions. The microorganisms need a steady supply of feedstock and a comfortable environment - warm temperatures, neutral acidity and no oxygen.

- 6. What is digested material and what is it used for? Digested material is the solid and liquid material that remains at the end of the anaerobic digestion process. Digested material contains valuable nutrients (nitrogen, phosphorus and potassium) and organic carbon. Typically, raw digested material is processed into a wide variety of products like fertilizer, compost, soil amendments or animal bedding. Factors influencing what products are made include the makeup of the initial feedstocks and local markets. These co-products can be sold to agricultural, commercial and residential customers.

- 7. What types of organic materials produce biogas? Many types of organic material can be used as feedstock to produce biogas. Animal manures, wastewater solids, food scraps, restaurant fats, oils, and greases, and by-products from food and beverage production are some commonly digested materials. An anaerobic digester may be built for a single material or a combination of them. However, the feedstocks must be properly controlled to ensure that the system remains healthy and functioning.

- 8. Is biogas a renewable energy source? Yes, biogas is a renewable energy source. It is produced from natural resources that are replenished in short periods of time.

- 9. Can biogas replace fossil fuels? Yes, biogas can replace fossil fuels for the production of heat, power and fuel. With additional processing, biogas becomes renewable natural gas that can be used in the same place as fossil fuels.

- 10. How does biogas help reduce effects of climate change? Biogas is made up of methane and carbon dioxide, which are powerful greenhouse gases. Anaerobic digesters are designed to capture these gases so they do not escape to the atmosphere. In most cases, the feedstocks used in digesters would have released methane directly as they decomposed in lagoons or landfills. In addition, using biogas for heat or electricity means that less energy needs to be produced by power plants. This reduces the amount of carbon dioxide emitted to the atmosphere by burning fossil fuels.

- 11. What types of facilities have anaerobic digesters? Anaerobic digesters are usually built on sites that have a steady supply of organic materials and need energy or heat. Common examples include farms, water resource recovery facilities, food production facilities, and landfills. Also, stand-alone digesters can be built in a central location to accept organics from multiple businesses.

- 12. Is there a difference between landfill gas and biogas? Landfill gas is a type of biogas. Both can be converted to renewable energy (electricity or fuel).

- 13. Is there a difference between natural gas and biogas? Biogas and natural gas have essentially the same components. But, the two gasses are obtained in different ways. Biogas is produced when readily available organic materials (e.g., manure or food waste) break down. Natural gas is produced when ancient plants, tiny sea animals, and other organic materials break down in hard to access locations. Usually, natural gas has to be extracted from underground reservoirs. Natural gas can also be derived from petroleum refining.

- 14. If I build a biogas system will it stink? Biogas contains a small amount of hydrogen sulfide, which has a rotten-egg odor. However, anaerobic digesters are completely enclosed and biogas is not released directly to the air. Digesters are commonly installed at farms to reduce odors. What comes out of a digester after processing is much less odorous than the feedstocks that go into digesters.

- 15. Are anaerobic digesters safe? A properly designed and operated system is very safe. Anaerobic digesters are designed to meet local and national codes for safety. However, they do produce methane and hydrogen sulfide. These gases both burn easily and are harmful to inhale, so it is essential to use proper gas-handling precautions. It is also important for plant operators to be well trained and follow established operational procedures.

- Step 1 Create a slurry by mixing the raw organic materials with water in equal ratios by weight. Empty the raw materials into a bucket and weigh it on the scale. Fill the second bucket with water until it is the same weight as the first bucket. Mix the raw material and water together and stir until an even consistency is reached.

- Step 2 Pour the slurry into the fermentation chamber of the biogas plant. Add seeding material (sewage waste) in an amount approximately twice that of the raw material by volume. For instance, if your raw material filled up one bucket, two buckets of seeding material should be added to the fermentation chamber.

- Step 3 Measure the pH of the slurry inside the fermentation chamber with the pH meter. In order for anaerobic bacteria to function well, a slightly alkaline environment is required. Neutral pH is 7.0, anything below that is considered acidic, anything above that is considered alkaline. Correct pH by adding more water or by carefully adding small amounts of lime to the slurry until the desired pH is achieved. Monitor and if necessary correct the pH throughout the retention period, or period in which biogas is being produced from the slurry.

- Step 4 Measure the temperature of the slurry using your thermometer. The ideal temperature is between thirty and forty degrees Celsius within the fermentation chamber, as this is the temperature range at which anaerobic bacteria are most active. If the temperature is too low, utilize a small heat source such as a space heater or if you live in a warm climate, dig a hole in the ground and line it with insulating materials and place the fermentation tank inside the hole. Monitor and if necessary, correct the temperature throughout the retention period.

- Step 5 Mix the slurry by stirring or agitating it thoroughly at least once per day throughout the retention period. The length of the retention period is dependent upon several factors such as temperature and slurry composition. However, a common retention time for this type of biogas plant ranges from two to four weeks.

In addition, undefined cultures (e.g. microorganisms in cow dung or waste water sludge) could be used as an inoculum for biogas production. Microbiological diversity and the regulatory role of hydrogen metabolism are considered as driving forces to optimize biogas-producing microbiological communities. Microbiological community analysis was undertaken with varying conditions and community members.

Environmental factors, which affect biological reaction, such as pH, temperature, nutrients and inhibitors compositions are amenable to the extrinsic control in the anaerobic action. Any forceful change in these parameters can adversely act on the biogas production. So, these factors should be adjusted in the desirable range to operate the anaerobic digester efficiently.

Even if manure has one of the highest potentials as feedstock for biogas, its relatively low methane yield is not always sustainable in economic sense. However, it can be enhanced with help of other substrates through co-digestion to achieve higher methane yields. Companies use, organic household waste as co-substrate in different concentrations of 5%, 10%, 15% and 25% to achieve higher methane yield.

To suggest operational improvements of DBD design the following set ups were studied using cow dung as a main substrate:

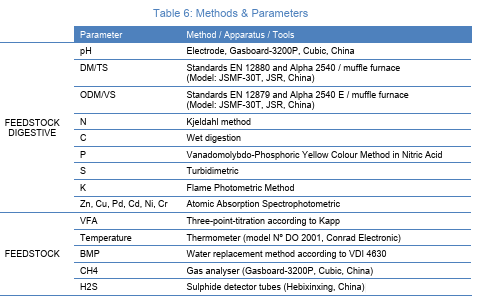

Two different type of digester: (1) imported prefabricated PVC Digesters, and (2) locally available converted rain water tank HDPE digesters. Different feeding intervals (daily, each 4th day, and each 7th day) of the digesters and its impact on biogas production. One step and two steps digesters, with and without hydrolysis. The performance evaluation was based on following parameters: pH, VFA, temperature (ambient/digester), temperature (biogas), biogas quantity (volume) and quality: CH4 (concentration), and H2S. The comparison of mono-digestion of manure and co-digestion of manure and organic waste showed that co-digestion produces higher methane yield and improved process stability, which has positive effects on economic sustainability of any biogas project.

However, co-digestion is only effective when used within right ratio, therefore, BMP measurements was carried out for more than 24 different mixtures during the period of 30 days. The performance of the different biogas digester types was observed for mono-digestion of cow manure in different feeding intervals and compared between daily, 4 (four) and 7 (seven) days intervals and its impact on biogas production: In case of converted water tank digester (WTD), co-digestion of organic waste with cow manure was evaluated in two different setups, (i) with and (ii) without hydrolysis to achieve higher methane yield.

The major objective of this exercise was to investigate performance differences of one-step and two-steps digestions for DBD. It is assumed that two-steps digestion with separate hydrolysis might increase process efficiency, at least regarding energy productivity. Each of the digesters was equipped with own gas storage bag (one gas bag for one step digestion / two gas bags for two step digestion). The HRT was about 30 days.

The following in very Important for Bangladesh Biogas Energy Plant:

- Dung from hybrid cow:

- Dung from hybrid cow:

- C: N ratio within the range but not optimal, due to relative high content of carbon.

- 1 kg of dry hybrid cow manure can produce 18–20 L of CH4.

- Highest yield of CH4 was achieved with hybrid cow – dry roughage 20 m3/t: 26 kg could generate 1 m3 biogas.

- In 35 days, 90% of the potential biogas was generated from dry CM, so longer HRT may be required for hybrid cow dung.

- Low N, P, K, S values of effluent.

- 2–3 hybrid cows would be necessary to supply enough gas for preparing two meals for an average size family in Bangladesh.

- Dung from local cow:

- C: N ratio is within the range but not optimal, due to the relative high content of carbon.

- With 1kg of dry CM from local cow it is possible to produce 19–22 L of CH4.

- Highest yield of CH4, also compared with dung from hybrid cows, was achieved by local cow – dry concentrate mix 22 m3/t: 24 kg could generate 1m3 biogas.

- HRT 35 days is enough for dry CM.

- Low N, P, K, S values of effluent.

- 2–4 local cows are necessary to supply enough gas for preparing two meals for an average size family in Bangladesh.

- Poultry dropping/manure

- C: N ratio is very low for anaerobic digestion, due to high nitrogen content.

- Mono-digestion with dilution ratio 1:1 (or less) of poultry manure with water or recycled effluent is not recommended.

- With 1 kg of dry PD it is possible to produce 25–26 L of CH4.

- Highest yield of CH4, was achieved from birds fed with non-commercial feed: 26 m3/t; 22 kg produce 1m3 biogas.

- Suggested HRT is about 25–30 days.

- Low N, P, K, S values of effluent

- 180–360 birds could supply enough biogas to prepare two meals for an average size rural family in Bangladesh.

- 5% of Organic Waste:

- Organic waste at concentrations of 5% was found very stable for anaerobic digestion. • Very good biogas quality was achieved, with average CH4 of 70–72% and low H2S <90ppm.

- Relatively high CH4 yield could be achieved from 73–93 m3t-1 per ton of substrate, the most yield by SO and FW mixture at 1:1, 7.5 kg would be enough to generate 1m3 biogas.

- To meet the estimated biogas demand of 0.8–1.6 m3, the daily amount of 6–12 kg of organic waste would be necessary. In contrast an average family could probably generate about 1.1 kg of organic waste, enough to produce around 0.145 m3 of biogas.

- To ensure the same conditions for anaerobic digestion with concentration of 5% or ORL at 0.56 kg ODM/VS/m3/d, to produce around 0.8–1.6 m3 of biogas, 2.4–6 m3 of digester volume would be necessary and HRT of 20 days.

- 10% of Organic Waste:

- Organic waste at concentrations of 10% was found not always stable for anaerobic digestion, as in the case of FW. Therefore, it is not recommended.

- Higher loading rate does not lead to higher methane yield.

- For 10% SO methane yield of 37 m3t-1 and 10% SOFW with 33 m3t-1 was achieved; the concentration of CH4 was very low at 46%.

- 15%, 25% of Organic Waste:

- 15% and 25% concentration of organic waste exceeding the degradation capacity.

- Stable digestion process was not achieved and therefore no biogas production took place, due to pH drop between 4.2–4.8 because of acidification caused by high VFA concentrations.

- Co-Digestion of 5% Organic Household Waste with Cow Manure:

- Co-digestion of 5% of organic waste with cow manure is stable for anaerobic digestion.

- Methane concentrations achieved averaged CH4 of 60–75% and low H2S <100ppm.

- In average, 13% more biogas and 24% more CH4 yields were achieved compared to mono-digestion of cow manure.

- To meet the estimated biogas demand of 0.8–1.6 m3, the daily amount of 19–38 kg of cow manure and 1–2 kg organic household waste would be necessary to meet the demand of an average family.

- To ensure stable conditions for anaerobic digestion with co-digestion of organic waste ORL at 0.86 kg ODM/VS/m3/d is required with 1.4–2.8 m3 DBD volume and HRT of 35 days.

- Co-Digestion of 10%, 15% and 25% Organic Household Waste with Cow Manure:

- Co-Digestion with 10%, 15% and 25% of organic waste with cow manure is unstable for anaerobic digestion due the pH drops.

- 5% of organic waste with cow manure is found more beneficial and within stable range for biogas production.

- Co-Digestion of 5%, 10%, 15% and 25% Organic Household Waste with Poultry Manure:

- Co-Digestion of 5% for organic waste with poultry manure has no significant

benefits in term of methane yield, therefore it is not recommended at household level. • At higher concentration of organic waste from 10%, 15% and 25% none of the trial could achieve stable biogas production. High concentration of organic matter exceeds degradation capacity and leads to high concentration of VFA and pH drop.

- Daily Feeding vs. 4th Day Interval:

- Overall biogas yield for feeding in 4-days intervals was 34% higher compared to daily feeding; methane yields 28% more.

- 48 kg of CM would be necessary to produce 1 m3 of biogas practiced as usual and 32 kg feeding in 4-days intervals.

- Performance of the digester could be increased without any additional investment cost, just by changing the feeding intervals; this might have potential to reduce labour time, too.

- In both setups, the digesters could produce enough biogas to cover daily theoretical demand (0.8–1.6 m3) for preparing two meals for the average family size in rural Bangladesh, with average daily biogas production of 1.6 N m3for LD and 1.1 N m3 for FD.

- pH and VFA are within the range and indicated process stability during the trial, for both digesters.

- The rule of thumb that 27 kg of CM can yield 1 m3 of biogas could be not confirmed. Based on daily feeding, 48 kg of CM would be needed.

- Daily Feeding vs. 7 Day Interval:

- There is not much difference to feed a digester on the daily basis or only once a week, with an average specific biogas production for FD 0.23 m3 BG/m3 DGd-1 and for LD 0.22 m3 BG/m3 DGd-1.

- Average methane concentration for a digester fed once a week was slightly higher with 62% than feeding on the daily basis 56%.

- Both setups could provide enough biogas to cover the estimated demand on biogas (0.81.6 m3) for preparing two meals for average size family in Bangladesh, with average daily biogas production of 1.1 N m3 for both feeding intervals.

- The rule of thumb that 27 kg of CM can yield 1 m3 of Biogas could be not confirmed. In case of daily feeding, 45 kg of CM would be necessary to produce 1 m3 of biogas, and 46 kg for feeding in 7-days intervals.

- One-Step – 1000L WTD water tank digester:

- Overall biogas yield of 79 N m3/t for feedstock mixture with (23%) CM, (5%) OW and (72%) re-circulated slurry, during the digestion with WTD, was above average and 60–73% more yield with lower investment cost, compared to mono digestion of CM in PVC tanks.

- Biogas production rate of the WTD with 0.8 N m3 BG/m3 DGd-1 is rated as good.

- 10 kg of CM and 2 kg of OW mixed with 31 L of DS would be necessary to produce 1 m3 of biogas and 1300 L of digester volume.

- In average the digesters could produce enough biogas to cover lower daily theoretical demand of 0.8 m3 for biogas (0.8–1.6 m3) to prepare two meals for average size family in Bangladesh, with average daily biogas production of 0.8 N m3.

New designs of DBD, the study team at BAU has come up with two new designs of DBDs based on the understanding gained on biogas production processes during the study. A SOP (Standard Operating Procedures) for the designs has also been developed. The main advantages of these new designs are:

- Expected production of about 30% more biogas from same amount of feed stock;

- Made of moulded plastic tanks available in the market leads to lower investment costs;

- Construction at site is estimated 1 to 2 days and gas becomes available in a week compared to much longer period for brick-cement models;

- Service life: 15 years or even longer; 5. Maintenance: Almost none; 5. Transportation: Weight being between 50kg and 200 kg; the tanks can be dismantled and are easy to transport;

- Mechanical property is good; i.e., no brittle in sun light;

- Insulation: good with low coefficient of heat conductivity;

- Tightness and resistance to acid corrosion is good;

- Water absorption rate is low; suitable for regions with shallow underground water table;

- The two designs have 3m3 and 5m3 volumetric capacity, with daily biogas production of 1.5 and 2.5m3 respectively; larger unit can be made modular;

- 1.5m3 biogas capacity DBD is good enough for a small family and can be operated in any two-cattle household; opening the DBD market for about 2 million households;

- Higher capacity model can be installed in a modular way together with two smaller units; such design could further reduce production costs;

- SOP require only twice a week feedstock loading, thus reducing labour input;

- Up to 5% soft vegetable, kitchen waste etc. could be used as feedstock;

- Production costs of these type of DBDs are estimated to be about BDT 30,000 for 1.6–1.8m3 of expected biogas production; resulting in less than 14% of the cost of currently installed brick-cement or 27% lower compared with fibre glass models. The listed advantages of the new design DBD are based on smaller volumes (1m3 and two chambers 0.5m3) experimental models. Scale models should be tested in a next phase within selected households to validate the design performance before market dissemination.

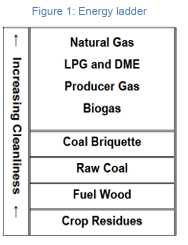

More than 90% of Bangladesh rural households are still using traditional biomass for cooking; biomass accounts for 50 percent of Bangladesh’s total energy supply. The commonly used fuels are rice husks, jute sticks, cow dung and wood. Unequal rates of economic growth between rural and urban Bangladesh has forced millions of rural citizens to remain on the lower ranks of the “energy ladder” and of society. The focus in the Bangladesh rural household energy policy on improved stoves and cleaner fuels stems largely from a desire to accelerate advancement along an “energy ladder” (Figure 1) and provide households with the benefits of cleaner, more efficient energy, which extends beyond reduction of Indoor Air Pollution (IAP) much sooner than it would occur by waiting for incomes to grow to levels high enough to allow households to buy cleaner fuels.

IAP borne illnesses are most severe among women and children. Women, on average, spend more time in the kitchen, where pollution levels are highest. They may also keep their children nearby, enhancing the children’s exposure to IAP. Also, the IAP disease burden is stronger in rural areas than in urban households. Figure 1: Energy ladder. Besides household based biogas production, neighbourhood biogas mini grids, or bottling (Torn, 2010) upgraded and compressed biogas (as bio-methane), there is currently no viable alternative for significantly increasing rural access to clean gas for cooking. Transporting natural gas tanks—Compressed Natural Gas (CNG) bottles—or establishing an extensive rural natural gas network are both relative expensive (Torn, 2010), and as in 20 years the natural gas reserves from Bangladesh will be depleted, the use of CNG is no more promoted for new applications. Although 4 percent—compared to 0.3 percent in 2004—of all Bangladesh households are now using mainly bottled LPG, and LPG is widely available in urban and peri-urban markets, it has largely failed to reach rural households (World Bank, 2010).

There is still few access to bottled LPG in remote rural areas. The Infrastructure Development Company Limited (IDCOL) is the premier infrastructure financier in the country, pioneer in channelling inclusive financing through several renewable energy and energy efficient projects/programs, and a pioneer in mass scale off-grid renewable energy dissemination in Bangladesh.

Started with the Solar Home System program in 2003, IDCOL has country-wide programs in solar home system, domestic biogas, solar irrigation, solar mini-grid, biomass and biogas based electricity generation plants. IDCOL offers a comprehensive range of subsidy and concessionary loans to these viable renewable energy programs/projects. In addition, IDCOL provides support for feasibility analysis, training and capacity building as well as for promotion and awareness campaign. While owned by the government, IDCOL itself is a public private partnership.

The aim of IDCOL is to catalyse and optimize private sector participation in promotion, development, and financing of infrastructure, renewable energy and energy efficient projects in a sustainable manner through public-private-partnership initiatives. Biogas specific experience from IDCOL started in May 2006 with small domestic biogas systems to produce cooking energy and soil improving bio-slurry within and for livestock keeping rural farm households. Under the framework of the National Domestic Biogas and Manure Program (NDBMP) the first biogas union of Bangladesh was officially recognized in May 2010.

Biogas can be produced from various organic substrates, which all are in general suitable for anaerobic digestion. However, technologies for biogas production require extensive pre-processes of feedstock. Feedstock for biogas production may be solid, slurries, and both concentrated and dilute liquids from a range of organic sources. There are several studies focused on the feedstock and related mixing scenarios with operating conditions to increase biogas production —i.e. (Aragaw et al., 2013; Pöschl et al., 2010)— shows that energy input is highly influenced by the characteristics of feedstock used. For instance, agricultural waste, in most part, does not require pre-treatment. Energy crop feedstock requires the respective cultivation energy inputs, and processing of industrial waste streams includes energy-demanding pre-treatment processes to meet stipulated hygiene standards.

Energy balance depends on biogas yield, the utilization efficiency, and energy value of intended fossil fuel substitution. The upgrading of biogas to bio-methane for injection into a natural gas network potentially increases the primary energy input for biogas utilization by up to 100 percent; but the energy efficiency of the respective biogas system improves by up to 65 percent when natural gas is substituted instead of electricity. It was also found that system energy efficiency could be further enhanced by 5.1–6.1 percent through recovery of residual biogas from covered digestate storage units.

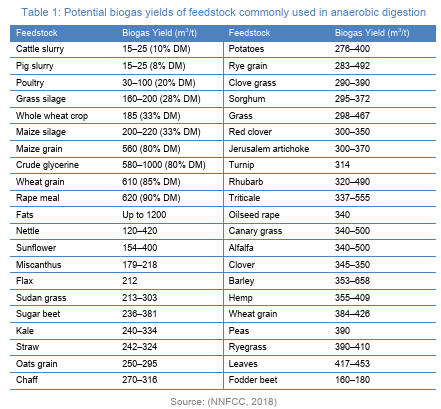

Feedstock Biogas Yield (m3/t) Feedstock Biogas Yield (m3/t) Cattle slurry 15–25 (10% DM) Potatoes 276–400 Pig slurry 15–25 (8% DM) Rye grain 283–492 Poultry 30–100 (20% DM) Clove grass 290–390 Grass silage 160–200 (28% DM) Sorghum 295–372 Whole wheat crop 185 (33% DM) Grass 298–467 Maize silage 200–220 (33% DM) Red clover 300–350 Maize grain 560 (80% DM) Jerusalem artichoke 300–370 Crude glycerine 580–1000 (80% DM) Turnip 314 Wheat grain 610 (85% DM) Rhubarb 320–490 Rape meal 620 (90% DM) Triticale 337–555 Fats Up to 1200 Oilseed rape 340 Nettle 120–420 Canary grass 340–500 Sunflower 154–400 Alfalfa 340–500 Miscanthus 179–218 Clover 345–350 Flax 212 Barley 353–658 Sudan grass 213–303 Hemp 355–409 Sugar beet 236–381 Wheat grain 384–426 Kale 240–334 Peas 390 Straw 242–324 Ryegrass 390–410 Oats grain 250–295 Leaves 417–453 Chaff 270–316 Fodder beet 160–180.

Challenges of Biogas Production on Bangladesh

The status of Domestic Biogas Digesters (DBDs) in Bangladesh was reviewed in 2011–2013 during the Biogas Audit Bangladesh (BAB) supported by KfW. So far, only the single-stage digestion system has been used in all the domestic plants in Bangladesh. All the four biological reactions (i.e., Hydrolysis. Acidogenesis, Acetogenesis and Methanogenesis) in the biogas generation process occur within a single, sealed reactor.

Using a single stage reduces construction costs, but results in less control of the reactions occurring within the system. Various issues involved in the DBD processes and operations are still not exactly known in the specific frame conditions of Bangladesh. As experienced in Nepal, for other household size biogas plants additional mono- or co-feeding materials like kitchen waste, soft green biomass and straw need to be pre-treated in different ways (soaking, hydrolysis, cutting) before feeding; also, the water mixing ratio based on estimated dry matter content need to be determined to keep the material homogenous.

According to Nepalese Table 1: Potential biogas yields of feedstock commonly used in anaerobic digestion Source: (NNFCC, 2018) experience, food waste and soft green waste should be mixed in small amounts with digester effluent as inoculum and stored in a container or the inlet tank for at least one day (24h). This mixture should be fed into the household biogas plants only in the late afternoon. Such operation recommendations should be analysed and tested for Bangladesh as well.

Not all organic materials are equally suitable for biogas production, therefore characterizing and analysing of feedstock is essential for any biogas project.