Due to their potential to lower greenhouse gas emissions and reliance on fossil fuels, Electric Vehicles (EVs) are a growingly well-liked form of transportation that has recently attracted much attention. Instead of using petrol or diesel fuel, an electric vehicle is propelled by an electric motor that draws power from rechargeable batteries. Three times as many electric vehicle (EV) users are anticipated by 2030 compared with 2011. This results from high-tech advancements in battery performance and how they affect vehicle autonomy.

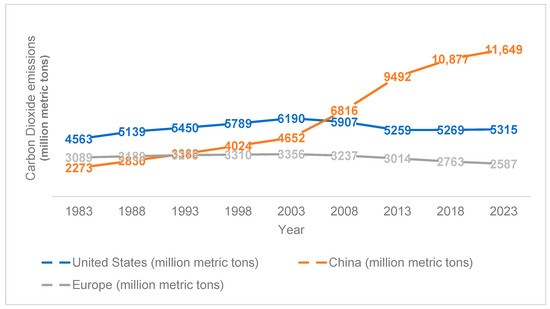

The environmental effect of electric cars is one of their main benefits. Figure 1 shows the energy-related carbon dioxide emissions in the US, China, and Europe from 1983 to 2023. While the sales of electric vehicles have been increasing in both China and the US, it is essential to note that these countries also have many traditional fossil-fuel-powered vehicles on the road. Additionally, the growth in energy demand in these countries has led to increased coal use, the primary source of carbon dioxide emissions.

Despite this, electric vehicles are still expected to significantly reduce carbon dioxide emissions in these countries in the long term. Unlike traditional cars, EVs don’t have tailpipe emissions. Even when the electricity they use is produced from fossil fuels, they still create less pollution than cars that run on gasoline. Because of this, EVs are a desirable alternative for those concerned about lowering their carbon impact. Electric cars come in various forms, such as battery electric vehicles (BEVs) and plug-in hybrid electric vehicles. (PHEVs). While PHEVs feature a battery and a conventional petrol or diesel engine, BEVs are powered by batteries. PHEVs can go a certain distance on electric power alone before the petrol engine takes over. Electric vehicles have advantages over conventional cars regarding cost-effectiveness and the environment. EVs might cost more up front, but they can save drivers money over time thanks to reduced fuel prices and less frequent maintenance needs. Since electric motors have fewer moving parts and require less maintenance, EVs also often have longer lifespans than conventional cars. Therefore, it’s a must to implement electric vehicles all over the world by reducing their adoption challenges.

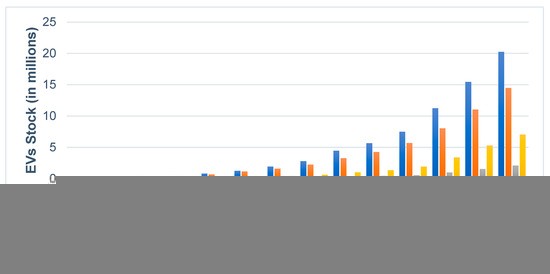

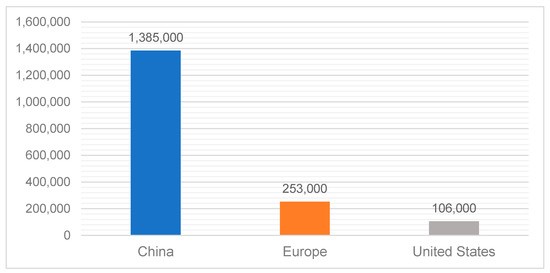

In this regard, government incentives play a critical role in increasing the sales of electric vehicles by making them more affordable and accessible to the public. China is a prime example of this, as the government has implemented various policies and incentives to encourage the adoption of electric vehicles. These include financial incentives such as subsidies, tax breaks, and free license plates, as well as non-financial incentives such as preferential access to carpool lanes and free parking. These incentives have helped to reduce the upfront cost of electric vehicles, making them more competitive with traditional gasoline-powered cars. In addition, government investments in charging infrastructure and research and development have helped to address concerns around range anxiety and the technology’s reliability. These incentives have resulted in a surge in electric vehicle sales in China, making it the largest market for electric vehicles globally. Figure 2 depicts the global electric car stock country-wise, including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs). China also holds the largest number of public EV charging stations, as shown in Figure 3.

It’s worth noting that these figures are constantly evolving as governments and private companies continue to invest in expanding their EV charging infrastructure. China has been particularly aggressive in building its charging network, intending to have 4.8 million charging points by 2025. Europe also invests heavily in expanding its charging infrastructure, with plans to have 1 million public charging points by 2025. The US is somewhat behind in the number of charging stations, but the Biden administration has proposed significant funding to help build the country’s EV charging network.

The classification and some of the advantages EVs offer over traditional vehicles are as follows:

2.3.1. Classification of Electric Vehicles

Vehicles that operate on electricity rather than petrol or diesel fuel are known as electric vehicles (EVs). There are several EV kinds, each with a unique engine and settings. According to their engine technology and settings, electric cars are categorized in the following manner in detail (Figure 4):

Battery Electric Vehicles (BEVs)

Battery Electric vehicles (BEVs): Rechargeable batteries are the only power source for BEVs, which are electric automobiles. They don’t have a backup generator or a petrol engine. Due to their lack of exhaust emissions, BEVs are regarded as the most ecologically beneficial form of electric car. However, they have a constrained driving range because the battery must be recharged.

Hybrid Electric Vehicles (HEVs)

Hybrid Electric Vehicles (HEVs): HEVs are electric cars with petrol engines and electric motors. An electric motor propels the car at low speeds and during acceleration. The petrol engine takes over at higher speeds and when greater power is required. Because HEVs utilize regenerative braking to recharge their batteries, they do not require plugging in. Although they use less fuel than conventional petrol cars, they have some exhaust emissions.

Plug in Hybrid Electric Vehicles (PHEVs)

Hybrid electric vehicles (HEVs) with bigger batteries that can be recharged by plugging a charging cable into an external electric power source in addition to internally by their on-board internal combustion engine-powered generator are called plug-in hybrid electric vehicles (PHEVs). They have a finite range of operations on electric power before switching to the petrol engine. PHEVs provide the ease of daily driving without a plug while allowing for electricity usage or on short journeys.

Fuel cell electric vehicles (FCEVs)

Fuel cell electric vehicles (FCEVs): FCEVs react hydrogen gas with oxygen in the air to create power. They don’t have a battery, and their sole waste is water vapour. Although FCEVs can be refuelled in a few minutes and have a greater driving range than BEVs, there is still a lack of hydrogen refuelling infrastructure.

Extended Range Electric Vehicles (ER-EVs)

Extended Range Electric Vehicles (ER-EVs) are a type of electric vehicle that combines the features of a Battery Electric Vehicle (BEV) and a Plug-in Hybrid Electric Vehicle (PHEV). ER-EVs have a larger battery pack than PHEVs, which allows them to travel longer distances on electric power alone. However, once the battery is depleted, a small gasoline engine generates electricity to power the electric motor and extend the vehicle’s range.

ER-EVs are becoming more popular as they offer the benefits of both BEVs and PHEVs. They can be driven purely on electric power for shorter trips and travel long distances without stopping and recharging the battery. ER-EVs are also more environmentally friendly than traditional gasoline-powered vehicles as they produce fewer emissions.

One example of an ER-EV is the Chevrolet Volt, which has a battery range of approximately 53 miles before the gasoline engine kicks in. ER-EVs are a promising option for consumers looking for a more sustainable mode of transportation but needing the flexibility to travel longer distances.

Each type of EV has its advantages and disadvantages. BEVs and FCEVs produce no tailpipe emissions and are considered more environmentally friendly, but their limited range and lack of infrastructure may be a challenge for some users. HEVs and PHEVs offer more flexibility and do not require new infrastructure, but they still produce some emissions and are less environmentally friendly than BEVs and FCEVs.

2.3.2. Benefits of Electric Vehicles

Environmental Benefits

Since EVs don’t emit tailpipe emissions, they don’t contribute to air pollution or greenhouse gas emissions. Even when fossil fuels are needed to generate energy to power the EV, it emits less pollution than a typical gas-powered vehicle.

Lower Operating Costs

Compared with regular cars, EVs offer lower running costs. In general, electricity is less expensive than petrol or diesel, and as electric vehicles have fewer moving components, they require less maintenance. Due to electric motors’ excellent durability compared with internal combustion engines, they also often have longer lifespans.

Energy Independence

Renewable energy sources, including solar or wind power, may power EVs. This lessens reliance on fossil fuels and may increase the sustainability of energy use.

Efficiency

Compared with conventional cars, EVs are more efficient. The efficiency of the power plant will also affect the well-to-wheel (WTW) effectiveness. Compared with diesel cars, which vary from 26% to 38%, the overall WTW productivity of petrol vehicles ranges from 12% to 28%. In comparison, the WTW efficiency of EVs powered by natural gas power plants ranges from 14% to 30%, while EVs powered by renewable energy show an overall efficiency of up to 70%.

Smooth and Quiet Operation

EVs operate significantly more quietly and smoothly than conventional cars because electric motors generate less vibration and noise. This may result in a more relaxing and pleasurable driving experience.

Convenience

EVs may be charged at residences or public charging stations, so going to the petrol station is no longer necessary. Additionally, many EVs include capabilities that enable drivers to remotely warm up or cool the cabin, which may be helpful in extremely hot or cold weather.

Performance

Electric motors can produce instant torque, allowing EVs to accelerate quickly. They could also have a lower centre of gravity, making them more manoeuvrable and stable.

Challenges of Implementing Electric Vehicles

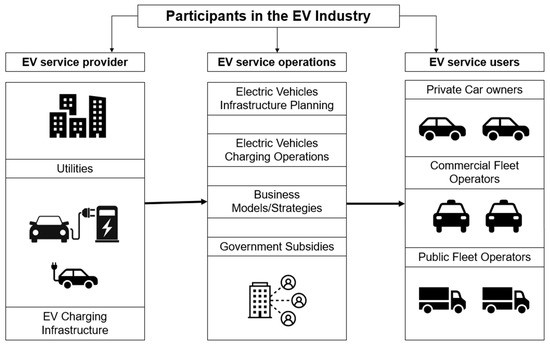

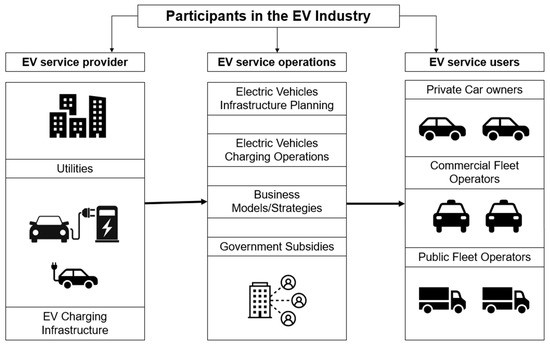

Public sector operators in the EV market include utilities, state and municipal governments, and private sector players, including EV service contributors, fleet workers, and individual car holders. Variable adopters, such as private automobile owners, managers of private business fleets, and public fleets, make varied operational decisions. Following the types and distribution of adopters, at-home charging, public charging, and battery-swapping stations should be optimized for the charging models. The customer type is also connected to incentive programs and infrastructure deployment. An overview of the EV service industry’s members and some of the key problems they deal with is shown in Figure 5.

According to this definition, an “EV” is any vehicle in which most of the driving energy comes from a battery of electricity. (e.g., battery electric vehicles [BEVs], plug-in electric vehicles [PEVs], and plug-in hybrid electric vehicles [PHEVs]). A BEV is powered only by its battery pack, which can be charged from the electrical grid. In contrast, PHEVs use an internal combustion engine, an electric motor for mobility, and a battery that can be charged from the power grid. BEVs and PHEVs are also called “PEVs”, which are EV varieties that can be charged using energy from the grid. Lithium-ion batteries are the most popular alternative for electric vehicles (EVs), followed by lead-acid, nickel-metal hydride, and sodium-nickel chloride batteries. Various charging levels can be used to recharge an EV’s battery. A battery requires 2–8 h to fully charge at level 1 or level 2, which is at 110–240 voltage, also known as ordinary charging, but level 3 (480 V), also known as rapid charging, requires just 20 to 40 min. The expense of an EV’s battery is still significant. From up to USD 800 (2012), the cost of electric vehicle lithium-ion battery bundles (per kWh) is anticipated to fall to USD 125 by 2022. Battery degeneration happens while the battery is stored, corresponding to annual aging, and when it is charged and discharged.

The EV sector differs from the traditional ICV industry in several ways, making challenges with growing EV service operations more difficult. Below is a summary of these broad problems.

3.1. Charging Infrastrcture

EV-related technologies are still developing; hence, their future course is yet unknown. For instance, one of the most important elements influencing EV acceptance is the battery performance, which is still not at its peak. Despite recent advancements in the construction of charging infrastructure, it is still not as accessible or practical as conventional petrol stations. This can make it challenging for EV drivers to locate charging outlets when needed, especially when travelling long distances or in remote places. The speed of battery recharging is another ambiguous technological aspect. It has long been anticipated that fast and secure charging will let Electric vehicles replace Individually Constructed Vehicles. Global-scale fast charging would, however, increase the stress on the electric grid and, as a result, pose several stability issues for power systems. Another source of misunderstanding in technical standards are those for charging interface standards. Prior agreement on recharging standards will be essential for developing the EV market, as more diverse standards require more significant infrastructure expenditure. Additionally, many charging standards make producing their goods more challenging for EV suppliers and automakers.

3.2. Interconnected Public Policies

The EV industry is still in its infancy, given the total dominance of Individually Constructed Vehicles in the international car market. The public sector has a crucial role in encouraging the use of EVs. Many nations are implementing various policies to make it easier for EVs to be introduced and consolidated into the market. These rules and associated laws cover gasoline taxation, carbon emission controls, public charging infrastructure, monetary incentives and public subsidies, and support for electric vehicle study and development. Incorporating three interconnected factors—investment in electric vehicle charging infrastructure, state subsidies, and public acceptance of EVs—will help to increase EV adoption. Various new decision-making difficulties must be resolved for these policies to be successfully implemented. Public policymaking is complicated and made more difficult by the high levels of uncertainty and market dynamics for EVs.

3.3. Business Strategies

How a firm or group of businesses provides one or more goods or services is called its “business strategy”. The EV sector has suggested cutting-edge ownership models, including battery swapping and EV sharing, to address problems such as range anxiety and high upfront costs. For this, the Beijing EV firm, a top electric vehicle manufacturer in China, set up battery switching places for electric taxi cabs in 2015. Sinopec, a firm benefiting from a vast transportation network, worked with Beijing Electric Vehicle Company to implement these stations.

Vehicle sharing is a well-liked type of business where people hire automobiles for brief intervals, frequently per hour/day. Customers can access a sizable fleet of automobiles by signing up for a car-pooling program and paying a yearly fee. EV sharing mixes the business concepts of EVs and automobile sharing. Many local states are increasingly pushing electric vehicle sharing schemes by providing numerous forms of monetary incentives because of the growth of the sharing economy. This approach is appealing since it enables users to utilize EVs on a budget. Car2go, a division of Daimler AG, runs a car-sharing program with all-electric fleets in San Diego (USA), Amsterdam (The Netherlands), and Stuttgart (Germany).

Therefore, it is probable that developing business strategies will provide several approaches to get over obstacles to broaden EV implementation. However, specialists and scholars must examine the pertinent issues with these service operations’ business models.

Strategies for Overcoming Challenges

It is generally known that, as compared with cars powered by internal combustion engines (ICEs), electric vehicles (EVs) have the potential to provide significant societal and personal advantages. Recent research has looked at the many obstacles EVs encounter and has typically determined that the most common ones are cost, range, infrastructure for charging, and customer perceptions.

Compared with refuelling ICEVs, the range of BEVs is presently constrained, and charging still takes much longer. As a result, route design is excessively optimistic, and some routes are too lengthy for battery electric vehicles (BEV). Therefore, this research paper proposes suitable strategies for implementing electric vehicles (EVs) in smart cities.

4.1. Charging Infrastructure

Since electric vehicles often have a smaller driving range than conventional vehicles, their owners may be concerned that they may run out of juice before reaching their destination. Even though the range of EVs is expanding, some drivers, particularly those who need to go long distances, still find it challenging. However, the consumer will be aware of the open slots if they can reserve charging times in advance. Customers can thus research alternative slots besides those already waiting in line. By answering consumers’ queries and easing their worries over the charging network, good charging infrastructure will also help to reduce their “range anxiety”.

There are several ways to effectively alleviate range anxiety, even if it makes customers unhappy and presents an economic hurdle to EV adoption.

First, fast DC charging is a practical method for reducing the time it takes to recharge and extending the range when travelling between cities by highway. Various driving styles have various energy and recharge requirements; thus, EV infrastructure planners should consider this. Properly and dynamically building EV recharging infrastructure helps alleviate range anxiety.

Second, a mathematical vehicle model that can forecast “real road” driving energy consumption and drivable range may be utilized to estimate accurate energy consumption and drivable range.

Third, developing countrywide charging stations can also help alleviate range anxiety, but this cannot be done without government incentives or public-private collaboration.

Finally, range anxiety can be decreased by using a network path selection model. For EV drivers, this model chooses the quickest and best route using an algorithm. These models, meanwhile, might be improved by judging the exit time and duration of a stop at a charging station. The driving range can be increased by employing series, parallel, and series-parallel charging arrangements with extremely efficient electric motors. To partially alleviate range anxiety, some EV manufacturers even provide complimentary rental automobiles for local trips outside the EV range.

4.2. Balancing Auxiliary Loads

Auxiliary loads greatly impact how much energy electric cars use, which cuts down on how far they can go. First, heavy auxiliary loads drain batteries in city driving circumstances, reducing the EV’s range. The driving range decreases by 17.2–37.1% (under simulated settings) when the AC is activated in the summer. Similar to how EVs employ PTC (Positive Temperature Coefficient) heaters, the range spans from 17% to 54% (under simulations) owing to the need for heating in the cold. Second, when electric cars are driven at highway speeds, the effects of auxiliary loads such as air conditioning and heating have not yet been fully investigated. Finally, there are significant differences in the impact of supplementary loads in a lab setting and on actual roadways. Under ideal conditions, such as with little auxiliary loads and the help of a regenerative brake system (RBS), electric vehicle producers may achieve low energy consumption and an extended driving range; nevertheless, this ideal outcome is different when EVs are driven on highways amongst towns.

One way to address the problem of limited range and high energy usage brought on by auxiliary loads is to utilize a heat pump to heat EVs in the winter. This can increase the driving range by 7.6–21.1% thanks to a higher heating coefficient of performance (CoP). The vapor compression cycle of a heat pump oversees both cooling and heating. Additionally, a four-way valve that reverses refrigerant flow is included. Additionally, its coefficient of performance is 1% greater than that of PTC heaters. Additionally, a precise assessment of EVs’ heating and cooling demands may significantly reduce the energy used by the AC system. An appropriate energy management technique can also lower the total energy consumption when cooling. Consequently, a suitable energy management strategy may regulate energy use instead of the ON/OFF technique.

Another approach is the system configuration that has been suggested, which uses a traction shaft to clutch the AC compressor motor during braking intervals. This method not only helps the EV to weigh less but also uses less energy.

4.3. Improved Battery Technology

The limitations of battery technology are one of the main obstacles to the widespread use of electric vehicles (EVs). The present battery design for EVs has a poor energy density, which impacts the vehicle’s driving range. To improve EV efficiency, a variety of battery technologies and combinations have been created over time. Users see electric vehicles as a real alternative to internal combustion engine vehicles because of the development of better, more affordable, and higher-capacity batteries, which will increase vehicle autonomy.

Since batteries are vital to EVs, more manufacturers (such as LG, Panasonic, Samsung, Sony, and Bosch) are investing in creating better, more affordable batteries.

The battery bundle is the costliest part of any EV. For instance, the Nissan LEAF’s lithium-ion batteries originally accounted for one-third of the total cost of the car. However, it is anticipated that this cost will gradually decrease; as of the end of 2014, the battery pack cost around $500 per kWh (half the price in 2009); now, the price per kWh is $200, and it is anticipated to drop to approximately $100 in 2025. The fact that Tesla Motors is creating a “Mega factory” to lower manufacturing costs and enhance battery output is another piece of data supporting the trend towards lower battery costs.

The price of EVs would naturally decrease because of decreasing battery costs, making them more competitive with other types of cars.

Figure 6 depicts the battery capacity of various EVs from 1983, when the Audi Duo was first sold, when it had an 8-kWh battery, through 2022, when Tesla claimed it would sell a Tesla Roadster with a 200-kWh battery. The GMC Hummer EV Pickup Edition 1 has the largest battery capacity at 212 kWh.

The following section discusses three issues with suitable proposals relating to EV battery technology, including battery nature, battery price, and electric vehicle chargers.

4.3.1. Battery Type

Technology for EV batteries must advance significantly to meet this demand. A good EV battery should be lightweight, affordable, safe, and long-lasting. It should also have a high energy density and a high-power density. The ability of a battery to hold energy is referred to as energy density. A gadget can be maintained and charged longer with a massive energy-density battery since it can store more energy. Cycle durability is also an important phenomenon in batteries. This is the number of “full” charge/discharges cycles the battery can tolerate before its capacity drops to under 80% in terms of its life cycle. If a battery is only 60% discharged and fully charged, it has not gone through a charge/discharge cycle. Depending on the battery type, the percentage may vary. The conclusion is that an EV battery shouldn’t have a short life cycle, as shown in Table 2.

Table 2. Battery Types

The battery’s memory effect describes a situation in which it retains the rate of its most recent discharge and won’t produce any more than that (even throughout a fresh charge/discharge cycle). Alternatively, the battery “remembers” how much of its capacity was used up the prior time and won’t supply it anymore. The memory effect is no longer a concern because of advancements in battery technology.

The discharge rate is the pace at which a battery expends or discharges energy. A high-discharge-rate battery is inappropriate for EVs since it cannot be utilized for extended durations while being charged. Numerous EV battery technologies exist; some are listed below:

- Lead-acid batteries are the first kind of batteries used in electric vehicles. These batteries are made of acid that produces electricity and lead electrodes. The electrolyte level needs to be checked frequently, and these batteries are hefty and have a low energy density. Additionally, they are not environmentally friendly.

- The second sort of battery is nickel-based, which is thought to be better developed and has a comparatively greater energy density. However, its shortcomings include low power density and poor charge/discharge efficiency. The memory consequences and insignificant performance in cold temperatures are further issues with nickel-based batteries.

- Batteries that are made of nickel metal hydride (Ni-MH) have negative electrodes, which are made of an alloy that can store hydrogen rather than cadmium (Cd). Many hybrid cars, such as the Toyota Prius and the second-generation GM EV1, employ these batteries even though they exhibit more self-discharge than nickel-cadmium batteries. Along with a lead-acid model, the Toyota RAV4 EV also came in a nickel-metal hydride model.

- Batteries made of zinc and bromine (Zn-Br2) are batteries that employ a zinc-bromine solution kept in two tanks and in which the positive electrode undergoes a bromide-to-bromine conversion. In 1993, a prototype named “T-Star” used this technology.

- Sodium sulfur batteries (Na-S) are made of sulfur and sodium liquid (S). This kind of battery has a large life cycle, a high energy density, and great loading and unloading efficiency (88–92%). They also have the benefit of these materials being relatively inexpensive. They may operate at temperatures between 300 and 350 °C, but the Ford Ecostar, a vehicle that debuted in 1992–1993, uses these batteries.

- Rechargeable lithium-ion batteries are a widespread energy storage system for computers, cellphones, and electric vehicles. They are renowned for having a high energy density, allowing for greater electric car driving ranges and longer battery life for electronic gadgets. To enable the movement of electrical current, the batteries employ lithium ions to transmit energy between the positive and negative electrodes.

- Batteries made of lithium-sulfur (Li-S), zinc-air (Zn-air), and lithium-air (Li-Air) are among the battery types used in the third category of batteries. Li-S is the least expensive of them all, thanks to the low price of sulfur, and it also has a high energy density.

When examined independently, Li-S has a rapid life cycle and a high discharge rate. Zn-Air is a “potential” future option for EV battery technology because its “theoretical/in-lab experiments” show a high energy density of 1700 W/kg, which is comparable to the conventional internal combustion engine. However, the major drawback of a Zn-Air battery is its low power density and short life cycle. However, it is still a prototype and not ready for purchase. Similar circumstances apply to Li-Air, which is still in the prototype stage and not yet on the market. For a detailed comparison of the various battery types, see Table 2.

Lithium-ion battery operation’s temperature and voltage windows define the battery’s safe and dependable operating range. As electrolytes begin to self-destruct above 150 °C, going over these limits would quickly reduce battery efficiency and may even cause a safety consequence (e.g., trigger a fire or explosion). The majority of EVs and PHEVs currently use this sort of battery.

Lead and zinc batteries perform worst in specific power (up to 100 W/kg), whereas Ni-MH and Li-ion batteries perform best (up to 1000 W/kg and 3000 W/kg, respectively). In terms of cell voltage, lithium-ion and sodium batteries (Na-S and Na-NiCl) need a higher voltage than batteries made of nickel and zinc. On the other hand, lead-acid and Ni-MH batteries provide the worst performance in terms of life cycles. Finally, whereas lithium batteries can sustain up to 3000 cycles, Na-S batteries perform better and can support up to 4500 cycles.

Since these battery types could increase the range of electric vehicles, further study is being done to enhance them. To guarantee the successful operation of electric vehicles, additional subsystems are included inside the battery system, such as a system to manage the batteries and an adequate thermal management system. When all the considerations are considered, current electric cars employ lithium-ion technology for their batteries since it performs the best across most of the analyzed qualities.

4.3.2. Battery Cost

Another EV difficulty that keeps it from succeeding on the market is the expensive price of batteries. Some key drawbacks of EV battery technology are a limited driving range, an expensive battery cost, prolonged battery charging time, unpredictable battery life, the excessive weight of EV batteries, and battery safety. As a result, a study should be done to create high-performance and affordable battery technology.

By 2025, battery costs are expected to drop by 70%, promoting EV adoption because of the high energy density. This is evident in the case of lithium-ion batteries (Li-Ion), whose price has drastically lowered because of their growing use in mobile devices and laptops.

4.3.3. Electric Vehicle Charging Devices

Most conventional electric vehicle charging devices are one-directional, making incorporating them into the system challenging. Nonetheless, this issue may be resolved using a bidirectional EV charger. Future “super-fast” direct current chargers are anticipated to be readily available in households, significantly reducing charging time. The smart grid may experience a decrease in load because of this advancement, and battery life may be extended. More study is required to advance this field, which also addresses EV battery technology, and overcome the EV charging problem.

4.4. Enhancing EV Charging Procedures—Battery Switching Stations

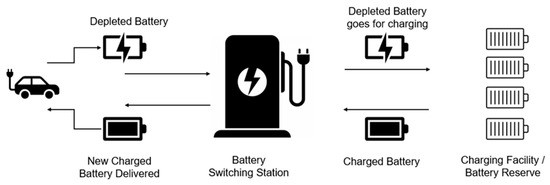

To lessen range anxiety, battery swapping stations might be utilized in place of battery charging stations. Standard, fully charged batteries are kept on hand at battery switching points for EV drivers to swap out and continue their trip quickly. In this way, EVs at a charge station along a highway can be changed immediately. The battery changing stations’ operational mechanism is depicted in Figure 7. This technology of charging EVs instantly is already being used by Tesla and U.S. and European battery vendors.

Most conventional vehicles can operate on any of the three fuels: petrol, diesel, and petrol, as shown by comparing traditional petrol stations and battery switching stations. Battery switching stations will need to handle a broad range of batteries, and they may run out of one type periodically. This might cause EV drivers to get anxious. Batteries come in various kinds: configurations, energy, and power densities.

EV drivers will be able to monitor the several battery types that are accessible thanks to smartphone applications developed by battery switching facilities. Even better, they may store extra batteries in advance to replace their exhaust ones. Giving the battery switching locations and the electric vehicle driver a communication platform can significantly reduce waiting times and eliminate range anxiety. This enables the driver to go beyond the usual velocity range of the vehicle.

However, this can present further issues for the battery switching stations, as they might need to keep many more batteries on hand to service clients, especially if some switch batteries numerous times daily. Multiple approaches can be used to solve this issue. The possibilities include limiting the number of swaps executed daily, adding a fee for each extra swap executed within a single day, penalizing customers for exceeding their daily limit, etc. As indicated, imposing fines may deter people from implementing EVs, so we need to consider which solutions are workable. Furthermore, the inconsistency of some battery types being available is another issue with battery switching stations. Due to the possibility that switching stations could not always have enough charged batterie, it might be challenging to service all their clients/EV drivers.

An EV battery-swapping station operator must continually modify charging and swapping guidelines to account for changing energy prices and save operational costs. A novel queuing network model with a service quality guarantee was used by to research the optimal charging procedures for battery swapping stations. They also updated the model to incorporate battery swapping facilities and renewable energy in the power system to flatten the power generation curve by considering locations and billing orders. A charging regulation was devised by for EV battery swapping stations. They recommended a hybrid particle swarm optimization and evolutionary method to determine the optimum course of action. To investigate the optimal charging/discharging method for a vehicle-to-grid (V2G) technology-based EV battery swapping station that enables two-way energy transfer between EVs and the power grid, ref. created a Markov decision process model. It was demonstrated that the best course of action was monotone, making it possible to compute it quickly. According to the techniques for battery exchange suggested on a scientific level, ref. also developed an in-line routing system for electric cars that permits replacing the batteries in BEs using Markov’s random choice processes. This method would reduce the waiting time by about 35%. Ref. developed robust optimization models to help with the planning process for battery swaps.

In this regard, it is worth noticing that battery swapping technology has gained significant traction in China. One of the key players in this space is NIO, a Chinese EV manufacturer, which has implemented battery swapping stations across China. These stations are fully automated and use a robotic arm to remove the depleted battery from the EV and replace it with a fully charged one. NIO claims that the entire process takes less than five minutes, providing a convenient and efficient way for EV drivers to continue their journey. They have installed over 1323 battery swapping stations across China as of March 2023.

Another company, called CATL, has developed a standardized battery swapping solution that can be used across different EV models. This approach provides flexibility for EV manufacturers and enables them to implement battery swapping technology without having to develop their own proprietary solutions. Furthermore, a study by McKinsey & Company suggests that battery swapping technology could account for up to 30% of EV charging in China by 2030. The study also notes that battery swapping can provide benefits such as reducing the cost of EV ownership, improving the utilization of EV batteries, and reducing the need for large-scale charging infrastructure.

Given China’s success in deploying battery swapping technology, other countries could benefit from learning and adopting similar techniques. Battery swapping provides a convenient and efficient alternative to traditional charging methods, which could help accelerate the adoption of electric vehicles and reduce reliance on fossil fuels.

Discussion

The analytical arrangements of the key studies are offered in this section to address all the research questions specified in Table 1.

RQ1: What are the main challenges and facilitators of electric vehicle implementation in smart cities, and what collaborative efforts are necessary for successful integration?

The main challenges faced in adopting electric vehicles in smart cities include range anxiety, high cost, lack of charging infrastructure, battery life and performance, and overall public acceptance and awareness of the benefits of EVs. Additionally, integrating EVs into existing transportation systems and policies, such as public transit and urban planning, can pose challenges, as described in Section 3.

Section 4.3 greatly describes the answer to this question. Firstly, with better battery technology, electric vehicles can have longer driving ranges, alleviating the range anxiety issue for drivers. In this regard, Figure 6 shows the battery capacity development from 1980–2025, how battery technology evolved, and how it still needs improvement. Secondly, more efficient, cost-effective batteries can lead to lower vehicle costs, making electric vehicles more accessible to a wider range of consumers. Section 4.3.1 describes the latest technology in batteries in this regard. Additionally, Table 2 shows the battery types and their characteristics. We can see that better battery technology can also enable faster charging times and more extended battery lifetimes, improving electric vehicles’ overall convenience and usability. However, focus should be on using renewable energy sources, such as solar and wind power, so that batteries can be charged without relying on traditional fossil fuels, thus reducing greenhouse gas emissions and promoting sustainability.

Section 4.4 explains how to improve the EV charging infrastructure that facilitates the implementation of electric vehicles. The authors extracted the data from recent research papers and divided the proposed strategies into flow and network stability models. To answer the question, the authors briefly summarized that the development of charging infrastructure and transportation could facilitate the implementation of electric vehicles in smart cities by addressing the challenges of range anxiety and a lack of charging stations. It involves deploying a charging station network in strategic locations such as parking lots, public spaces, and highways. The charging infrastructure should be convenient, reliable, and accessible to users. Promoting public transportation can encourage the use of electric buses and trains, reducing the number of personal vehicles on the road and reducing carbon emissions. Additionally, battery swapping stations might be utilized in place of battery charging stations to lessen range anxiety. In this regard, Figure 7 demonstrates the working mechanism of battery switching stations.

RQ2: How have electric vehicles contributed to reducing carbon emissions, and what is their global market share trend over time?

Section 2.3 thoroughly overviewed the electric vehicles, their classification, and their benefits to answer this question. Figure 2 shows the global electric car stock country-wise, including battery electric vehicles (BEVs) and plug-in hybrid electric vehicles (PHEVs).